lcd screen structure brands

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Toshiba is a famous multinational company with a history of 130 years. It covers a wide range of businesses, including social infrastructure construction, home appliances, digital products, and electronic components. It covers almost every aspect of production and life. Toshiba has the largest research and development institution in Japan. Through unremitting innovation and development, Toshiba has been at the forefront of science and technology in the world.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

... and dusty conditions. Plus, the protective glass serves to protect the display against sharp foreign objects, meaning the screen is still operable even with scratches on the surface.

... be used on the screen to maximize safety and hygiene. Plus, white-colored housing makes it easy for users to detect and remove dust or any other foreign substances.

... with a complete digital advertising solution. The wall-mounted outdoor display combines a high-bright screen with a weatherproof body. The 1,500 NITS screen captures attention, and auto-dimming keeps ...

... engaging digital signage in any weather. The high-brightness LCD screen keeps your content clear in direct sunlight, for maximum customer engagement. An IP54/NEMA 4 enclosure protects the screen ...

... turn-key system solutions in a stainless steel enclosure as wall, floor or ceiling mounting versions. The screen of the POLARIS Remote 15"" is a TFT display with an XGA resolution (1024 x 768 pixels) ...

... the main display for applications requiring a small screen. End-cap shelf displays in retail settings or as personal gaming screens as part of a larger interactive gaming table benefit from the features and design of ...

An LCD monitor is a flat screen using liquid crystal technology to create the display. It is used in place of CRT (cathode ray tube) monitors to display all types of verbal or graphic information.

These monitors are used wherever displays are necessary, including numerical control screens for machine tools, human-machine interfaces (HMI) or simply as industrial computer screens.

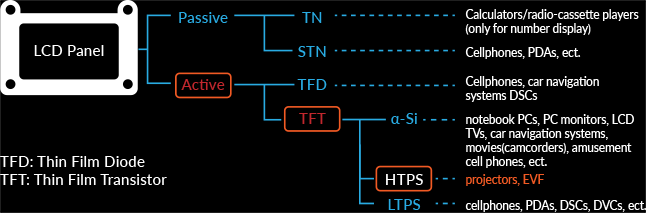

LCD monitors are among those that control the transmission or reflection of a separate light source rather than generating their own. The various technologies include twisted nematic (TN), super twisted nematic (STN), film compensated super twisted nematic (FSTN) and thin film transistor (TFT).

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

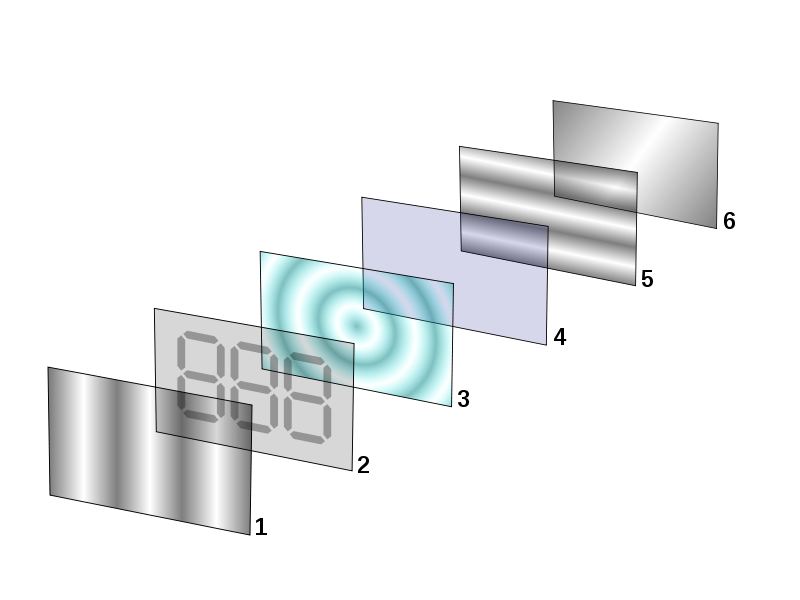

Segment LCDs, also called static displays or glass-only displays, are constructed of two pieces of ITO (Indium tin oxide) glass with a twisted nematic fluid sandwiched in between. A static display is a segment display with one pin for every one segment.

These displays are still one of the most popular technologies in use and the majority of them are custom. Many people think the process of designing a custom segment liquid crystal display is complicated and too complex to be understood except for a few experienced people. But after designing custom LCDs for over 14 years, it can be said that just about anyone can select the best options for their product.

In other words, you don’t have to be an engineer, or have a PHD from MIT to design a custom LCD for your application. So instead of offering a list of technical terms and equations, these are the different options available.

The tooling fee for a custom display is the lowest of all the technologies and allows the customer to receive a LCD that is manufactured to the exact dimensions requested, including custom icons and segments.

Focus LCDs offers a one-time NRE (Non-recurring engineering) or tooling fee. This includes all design, technical support, and samples. A PDF showing an overview of our tooling process can be found by clicking here: Custom LCD flowchart

Segment displays require less power than other display technology such as TFT, OLED, and UWVD. This makes these LCDs ideal for applications that are battery powered or solar powered. They require the lowest power to drive, an estimated 2uA per centimeter squared. Glass only displays (no backlight and no controller) require an estimated 10% of the power that is required for a LED backlight. In other words, a static display without a backlight will draw around 1mA; the same display with a LED backlight will demand from 10mA up to 25mA. Most displays can be driven at 3.3V or 5V since microprocessors can operate at both voltages. 3.3V is becoming more popular since two double ‘AA’ batteries can produce between 3.0V and 3.3V.

A segment is any line, dot or symbol that can be turned on and off independently. The photo below is of a segment LCD that contains numbers, a small clock symbol, the word ‘Jul’, and the letters ‘PM.’

There are four numbers in the above LCD (0 8 4 7) all are seven segments. In other words the ‘0’ has seven segments, the ‘8’ has seven segments and so on. Each number has seven independent segments. Each segment can be turned on and off independently to create other numbers and some letters such as E, F C and others. This is an example of a ‘seven’ segment. But there are some letters that a seven segment cannot display such as the letter ‘M’ or ‘V’. In this case a fourteen segment configuration can be used.

An icon is a small symbol or set of words that is only one segment. In other words, when the segment is ‘on,’ the full word or symbol turns on. When it is “off,” the word or symbol turns off. In the photo above: the clocksymbol is one segment, the word ‘JUL’ is one segment, the letters FOCUSLCDS.COM are one segment and the letters ‘PM’ are one segment.

It is possible to burn a segment into the glass so that it is always “on”. In this case, the ‘FOCUSLCDS.COM’ has been burned into the glass and can always be seen by the customer even when the power is “off”. Some customers will have their company name burned into the glass.

Segment LCDs, like all LCD display technologies, operate best between specific temperature ranges. You choose the temperature ranges that it will operate in. There are two standard configurations: normal temperature and wide temperature. The wider the temperature range, the more expensive the display.

The standard operating temperature range for a segment LCD is 0C to 50C. It is possible to build the display with a different fluid that will allow it to operate from -30C to 80C (F). With the addition of a heater, the display can operate down to -50C.

One of the advantages of designing a custom display is the ability to reduce your LCD display’s thickness by selecting a thin ITO glass; which is key to a thin LCD module.

The structure of the LCD is very basic, but a special glass called ITO glass is used in constructing the display. Three sides of the ITO glass are glued together with an adhesive or epoxy. Both the ITO glass and the nematic fluid used are transparent. There is a small gap of one or two millimeters between the top and bottom layer of glass. A nematic fluid is then injected between the layers. Finally, a cap is placed on the fourth side to keep the fluid from leaking out.

A polarizer is applied on both the top and bottom layer of glass. The polarizer on the top layer is always Transmissive, whereas the bottom layer can be Reflective, Transflective or Transmissive. For more details on the different types of polarizers, please read our article: LCD Polarizers.

ITO glass can be cut to custom dimensions, but smaller sized glass can add a significant cost increase to the overall cost of the LCD. The reason for the increased cost is the amount of labor and time required to add a polarizer to the small piece of glass.

Many times customers require the display to be as thin as possible; one method to achieve a thin LCD module is to select a thinner ITO glass. Keep in mind that the thinner the glass, the more expensive and the higher the fallout rate.

Note:Fallout rate does not mean failures of the LCD’s in the field; fallout is when the display fails on the manufacturing line. If the display fails in production, it is discarded before it is shipped to the customer.Once the display passes QA (Quality Assurance) it will operate normally for the life of the product.

It is possible to add a backlight to the monochrome display to make the display readable in low or no light conditions. The challenge of adding a LED backlight is that it increases the thickness of the LCD by as much as 5mm to 9mm.

In the photo above, a segmented LCD is combined with a LED backlight and backlight diffuser. A printed circuit board (PCB) is used to hold the assembly together. As the backlights name suggests, a light is placed behind the bottom layer of ITO glass.

Note: A backlight diffuser’s job function is similar to the lamp shade used on a table lamp. It disperses the light from each led to provide a more uniform appearance. Without the diffuser, there would be hot and cold spots on the display. A hot spot is where the backlight is too close to the LCD glass and it is overly bright; the area around the hot spot is dimmer and is referred to as a ‘cold spot’.

There are four methods to reduce the thickness of the LCD display/backlight combination; thereby creating a thin LCD module. However, these solutions do not apply to TFTs, VFDs, LEDs or OLEDs (Organic Light Emitting Diodes).

In the integration the backlight is sandwiched between the LCD and PCB. The LCD’s leads (pins) are then soldered to the PCB securely holding the backlight in place. This helps to create a thin LCD module.

Advantages of a PCB mounted LED backlight:The PCB combines the backlight and the LCD; this is great in applications that operating in environments of heavy vibration.

Another way to combine the LCD and the LED backlight is to use either a plastic clip to bind them together, or to use an epoxy or adhesive. There are advantages and disadvantages to both, but we suggest the plastic clip solution.

This method requires a one-time tooling fee to design and prototype a small, flexible plastic clip that holds the backlight and display together. The clip only adds a few pennies to the overall cost of the LCD combination.

This method is accomplished without any tooling cost and only adds a penny or two to the overall cost of the LCD assembly, but we do not recommend this approach.

An edge-lit display means that the LEDs are not placed behind the bottom layer of glass, but along the edge between the two layers of glass. This alone helps to create a thin LCD module.

Disadvantages to an Edge-lit display:One of the Challenges of this solution is that it increases the size of the overall display in the X and Y directions (Length and Width). Which means the sides of backlight will stick out beyond the LCD.

Side-lit displays work well for smaller size LCDs, but create hot spots around the edges if the display is too large. This is more evident with a white LED edge-lit; since white LEDs are much brighter than other colors and sometimes need to be dimmed to reduce their starkness.

EL backlights are AC (Alternating Current) driven, this requires an inverter either on the LCD or on the customers’ board. Inverters add extra cost and labor.

LEDs are DC (Direct Current) driven and do not require an inverter. Many times the voltage for the LED backlight is the same as for the LCD which means one less power supply is required.

We all spend hours looking at LCDs at home and at work as well as on our boats. But how many of us know how they work or—more importantly—how to choose a good one? Equipment manufacturers bombard us with snippets of information, but what does it all mean? Is a QVGA better or worse than WXGA? Just how big is a nit? And is CCFL on its way in or out?ADVERTISEMENTThanks for watching!Visit Website

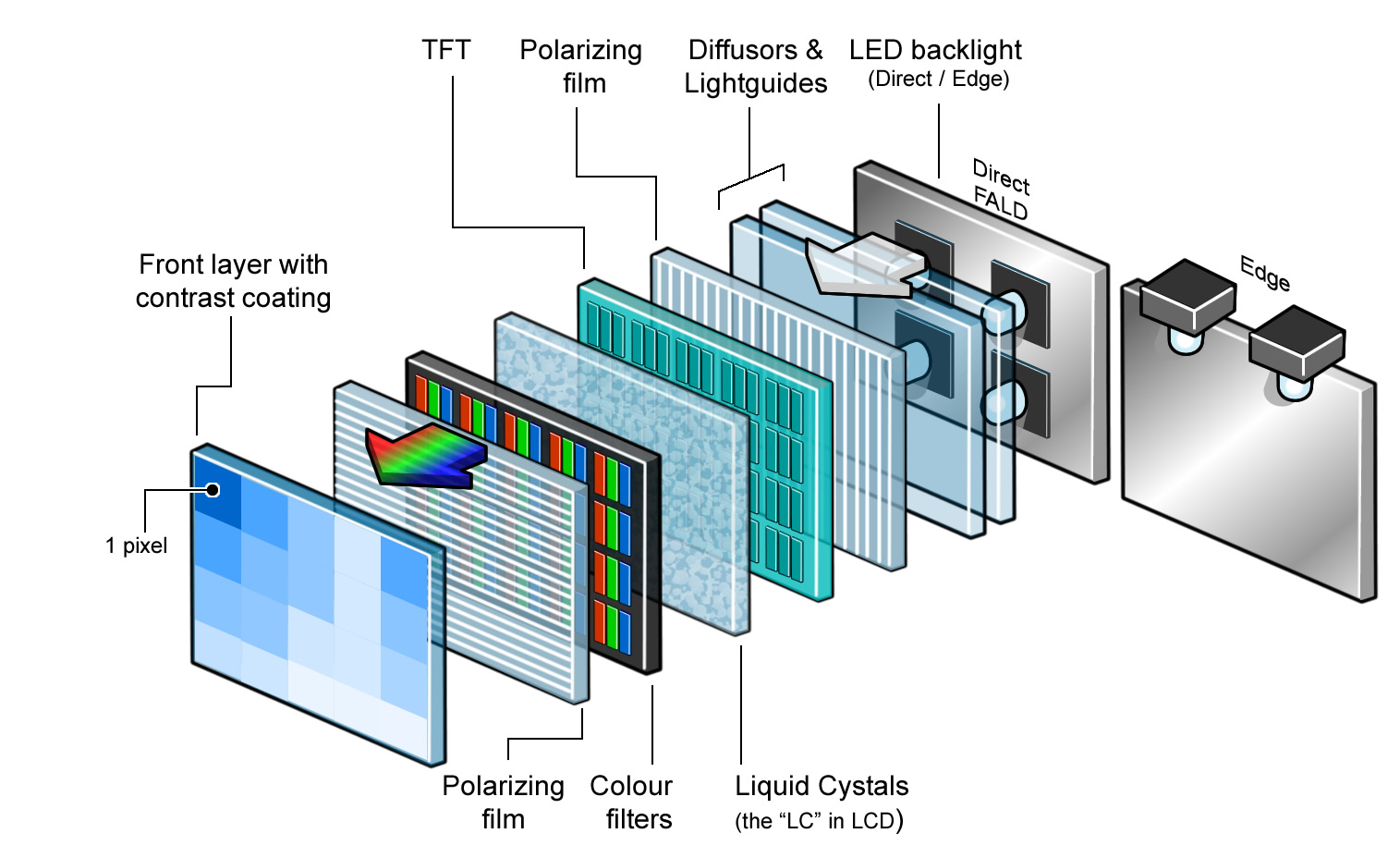

To start at the beginning, LCD stands for Liquid Crystal Display, a high-tech sandwich with a layer of liquid crystals at its heart. But just as it takes more than beef to make a burger, it takes more than liquid crystals to make a display.

Two particular properties make liquid crystals special. The first one is that they combine the shape-shifting ability of a liquid with the regular molecular structure of a solid and can be persuaded to change from one to the other when an electrical voltage is applied to them. The other one is that they can transmit and change polarized light.ADVERTISEMENTThanks for watching!Visit WebsiteADVERTISEMENTThanks for watching!Visit WebsiteADVERTISEMENTThanks for watching!Visit Website

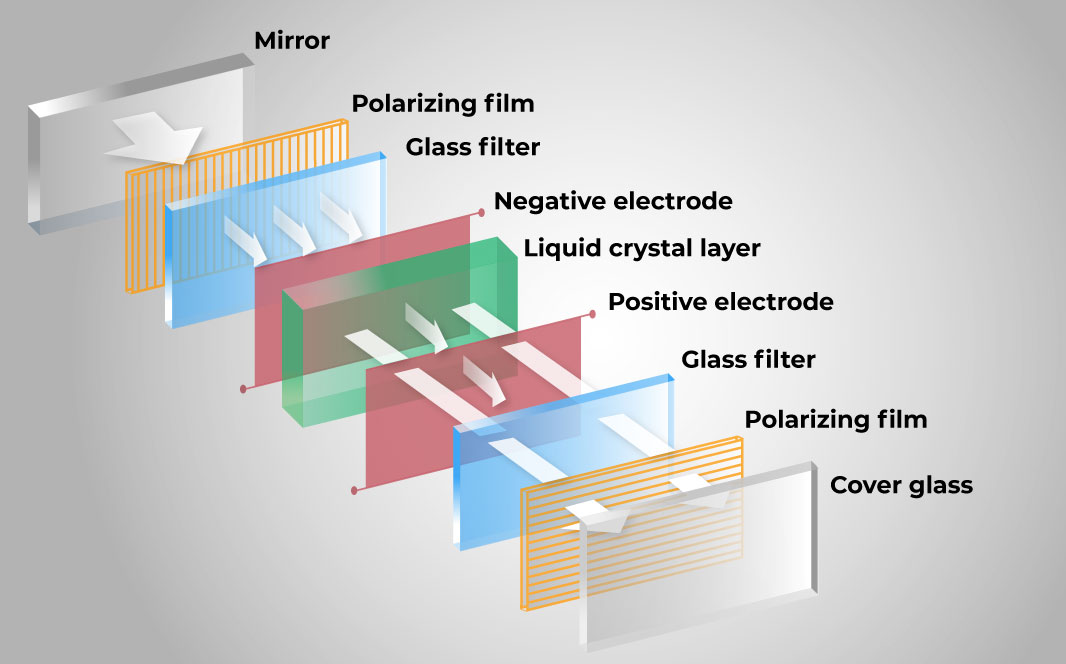

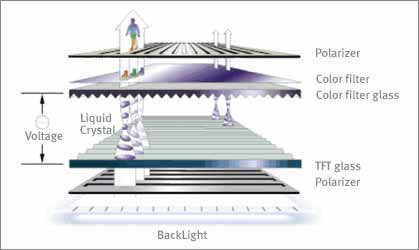

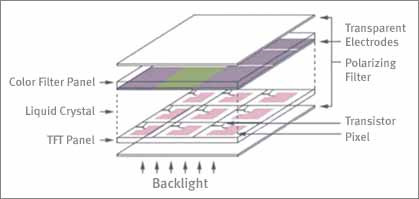

A very simple LCD is made up of seven layers. (See illustration below.) At the back of the screen is a layer of film that polarizes the light from the display backlighting so that all the electromagnetic waves that make up light are going in the same direction. Then comes a glass filter etched with a pattern of ridges and furrows, like a plowed field but reduced to molecular scale. Then comes one of the electrodes that will apply a voltage to the liquid crystal.

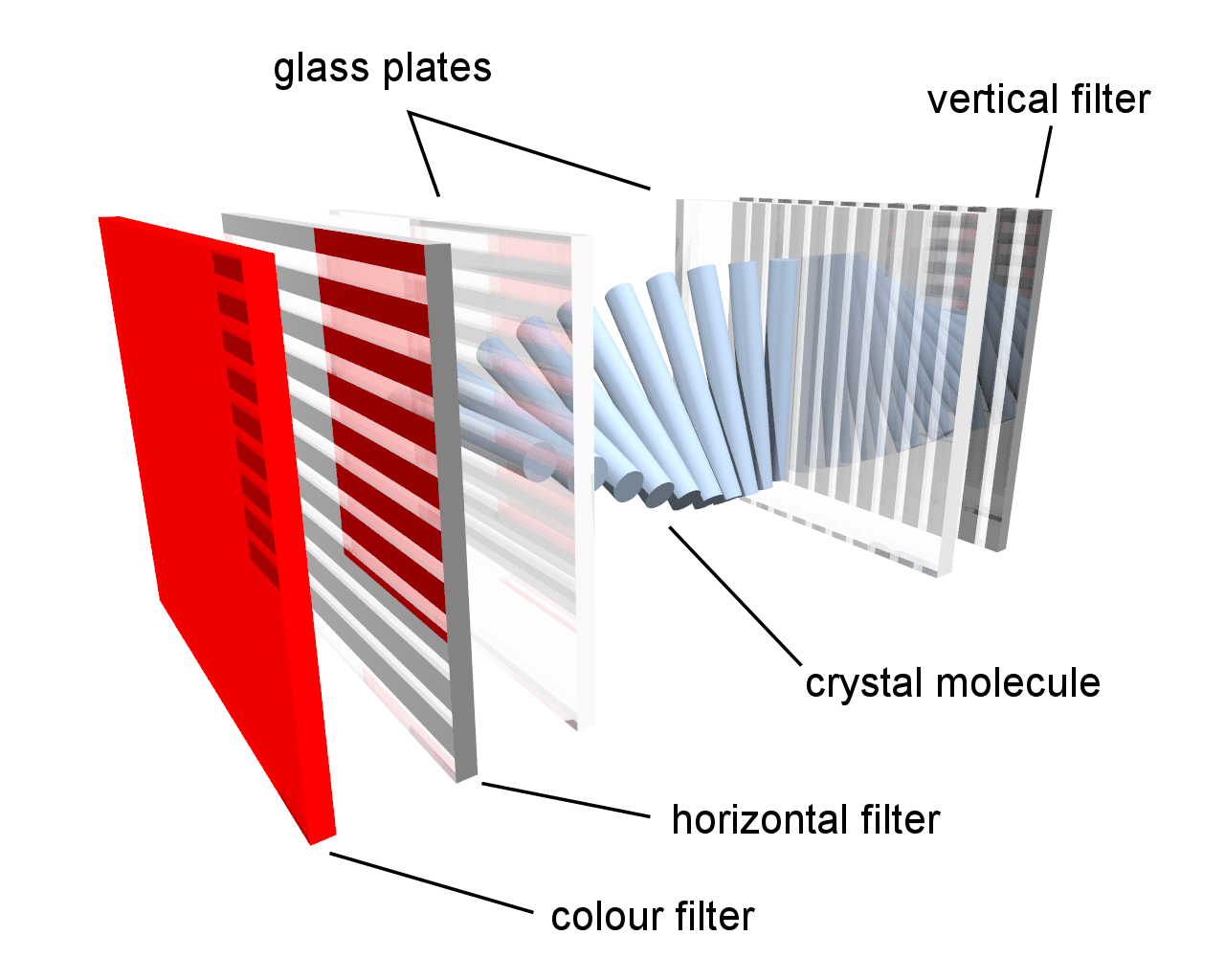

Any experienced boater has undoubtedly owned a pair of polarized sunglasses and so can probably appreciate how light can pass through two pieces of polarized film as long as they’re polarized in the same direction but is blocked if you rotate one of the films through 90 degrees. So our LCD sandwich would be opaque if it were not for the liquid crystal’s ability to change the polarization of light. The tiny furrows in the glass filters force the molecules of the liquid crystal to arrange themselves in a twisted pattern, so that they twist the polarization of the light that passes through them—allowing it to pass straight through the whole sandwich. But when an electrical voltage is applied to the liquid crystal layer, it overrides the twisted structure of the liquid crystal and forces the molecules to line up with each other. In this situation, the polarized light no longer twists as it is passed through the liquid crystal, so the sandwich becomes opaque.

Controlling such huge numbers of pixels and subpixels would be completely impossible if screen makers were still using the grids of wires that controlled the simple LCDs of the ‘70s. What made modern displays possible was a development known as Thin Film Transistors (TFTs) in which thousands of tiny transistors can be built into a thin transparent film and used as miniature switches to control the individual pixels of the display. It’s thanks to TFTs that we saw a sudden shift from the crude, blocky, monochrome displays of the ‘70s and ‘80s to the much higher-definition color displays of the late ‘90s.

Many TVs use LCD (Liquid Crystal Display) panels that are lit by LED backlights. There are two popular types of LCD panels: In-Plane Switching (IPS) and Vertical Alignment (VA), and there are two main differences between each type. A VA panel usually has a high contrast ratio and narrow viewing angles. However, an IPS panel has low contrast and wide viewing angles. These are the main differences between each, and for the most part, panel type doesn"t affect other aspects of picture quality, like peak brightness, color gamut, or color accuracy.

For the purposes of this article, we"re going to compare two LED-backlit LCD TVs: the Sony X800H, which has an IPS panel, and the Hisense H9G, which has a VA panel. Due to their different panel types, there are three noticeable differences in picture quality: viewing angles, contrast, and black uniformity, so we"re going to look at each one.

Our black uniformity tests determine how well a TV displays a dark scene with a bright image in the center. Ideally, you want to see a completely black screen with the center cross being the only part that"s lit up, and this is important for people watching movies. No LED TV has perfect uniformity, and unlike viewing angles and contrast, the panel type doesn"t completely determine its black uniformity. However, most VA panels that we"ve tested have good black uniformity, while most IPS panels have sub-par black uniformity. This doesn"t mean that every VA panel TV has good uniformity, as this can change between units, and you can also improve uniformity using the local dimming feature.

As you can see in the pictures above, the Sony has uniformity issues with backlight bleed and clouding throughout. The entire screen also looks blue due to the low contrast ratio. The Hisense"s screen is much more uniform, and although you can see some backlight bleed along the edges, it disappears if you enable local dimming, as seen in this photo.

LCDs function by having liquid crystals in little groups to form the pixels. These crystals react and change position when charged with electricity and, depending on their position, they allow a certain color of light to pass through.

Samsung released quantum dot TVs in 2015, which they later labeled as QLED in 2017. These TVs include a quantum dot layer between the LED backlights and the LCD panel to achieve a wider color gamut. Other companies like Vizio and TCL also use this quantum dot technology on their TVs. Adding this extra quantum dot layer doesn"t change the characteristics of the panel type; the VA panel on the TCL 6 Series/S635 2020 QLED still has a high contrast ratio and narrow viewing angles. Although most QLED TVs use VA panels, you can easily use an IPS panel as well.

Manufacturers have tried different techniques to improve the viewing angles on VA panels over the years, aiming to produce a perfect LCD panel with both wide viewing angles and high contrast. While they have yet to achieve that goal, a few TVs have hit the market that try to combine the best of both panel types. The first TVs with this viewing angle technology came out in 2018, and only a few high-end models like the Samsung Q90/Q90T QLED and the Sony X950H had this technology in 2020. These TVs are a bit unique, delivering noticeably better viewing angles than their pure VA counterparts, but still worse than true IPS panels. This comes at the expense of a lower contrast ratio, as these TVs have worse native contrast than most VA panels, but they"re still better than IPS panels. Combined with their local dimming features, they still produce deep blacks.

There’s a variety of display panel out there and even more on the way. But looking at all the different types of panels can be baffling. They come in various acronyms, and many of those acronyms are confusingly similar. How do LCD, LED and OLED compare? What about the different types of LCD panels? And how do these different technologies impact your viewing experience for things like gaming? To help, we’ve created this guide so you can gain a firm understanding of today’s display panel technology and which features really matter.

The first type of panels we’ll cover are LCD (liquid crystal display) panels. The main thing to understand about LCD panels is that they all use a white backlight (or sidelight, etc.). They work by shining a bright white light into your eyes, while the rest of the panel is for changing this backlight into individual pixels.

LED stands for light-emitting diode. You’ll often see LCD panels that are LED, but that doesn’t necessarily mean much when choosing an LCD. LED is just a different type of backlight compared to the old cold cathode backlights. While you could congratulate yourself on not using mercury, which is found in cathodes, at this point all LCDs use LED backlights anyway.

The second thing to understand is that LCDs take advantage of a phenomena known as polarization. Polarization is the direction in which the light wave is oscillating, or swinging back and forth at the same speed. Light comes out of the backlight unpolarized. It then passes through one polarizer, which makes all the light oscillate the same way.

Then there’s the “liquid crystal” part. A liquid crystal in this case is a crystal structure that can change the polarization of light passing through it. A liquid crystal in the rest, or off, state is arranged to not change the polarization of the light. This means that when the light reaches a second polarizer, oriented oppositely from the first polarizer, all the light is blocked. But when you apply a voltage, you turn the liquid crystal into some percentage of an “on” state. This then changes a percentage of the polarization of the light passing through to meet the orientation of the second polarizer, allowing it to pass through and become visible to your eye.

Now you have an on and off (and between) switch for light. To produce color all that’s needed is three color filters, red, green and blue, that block all light other than that color from coming through. The difference between different types of LCD panels is mostly in how this in-between liquid crystal part works.

This structure produces deeper blacks and better colors than TN panels. And multiple crystal alignments (shifted a bit off axis from each other) can allow for better viewing angles compared to TN panels.

IPS stands for in-plane switching. These panels debuted after TN panels in the mid-1990s. The crystals are always horizontal to the two polarizers and twist 90° horizontally to go from off to on. Part of this design requires the two electrodes (which apply current to the liquid crystal to change its state) to be on the same glass substrate, instead of aligned with each other on the sandwiching glass substrates above and below the crystal (as in other types of LCDs). This, in turn, blocks a bit more light than both TN and VA panels.

IPS panels have the best viewing angles and colors of any LCD monitor type, thanks to its crystal alignment always lining up with the viewer. And while they don’t offer as fast a response time or refresh rate as TN panels, clever engineering has still gotten them to 144hz, and with nice viewing angles you’re not necessarily going wrong with an IPS gaming panel.

How do LCD panels go about reaching HDR brightness when incorrect polarization and color filters block so much light?The answer is quantum dots. These clever little things are molecules that absorb light and then re-emit that light in the color you engineered them to.

Today’s quantum dot layers usually go between a blue backlight and the polarization step, and are often used to produce red and green that more closely matches the color filters, so more light passes through them. This allows more of the backlight to come through instead of being blocked by the color filters, it can also reduce crosstalk, or colors slipping through the wrong subpixel, ensuring better colors of LCDs.

Other uses of quantum dots are being tried, however. One promising one is using QD molecules to replace the color filters entirely, allowing even more light through. Because LCD backlights produce more light than OLED panels (more on those below), this would allow LCDs to become the brightest displays around.

Motion blur/ghosting can be a result of how long an image takes to switch from one to another and how long an image is displayed on screen (persistence). But both of these phenomena differ greatly between individual LCD panels regardless of underlying LCD tech. And both are often better controlled by higher refresh rates, rather than clever panel engineering, at least for LCD displays.

Choosing an LCD panel based on underlying LCD tech should be more about cost vs desired contrast, viewing angles and color reproduction than expected blur, or other gaming attributes. Maximum refresh rate and response time should be listed in any respectable panel’s specs. Other gaming tech, such as strobe, which flashes the backlight on and off quickly to reduce persistence, may not be listed at all and is not part of the underlying type of LCD used. For that kind of info you’ll have to check the detailed reviews here on our site.

OLED, or organic light emitting diode, panels, are different from LCDs. There are no polarization tricks here. Instead, each pixel (or subpixel of red, green, or blue) lights itself up as a voltage is applied to a giant complex molecule called, yep, an organic light emitting diode. The color emitted is dependent on the molecule in question, and brightness is dependent on the voltage applied. OLEDs can reach HDR brightness because their molecules put out the right colors to begin with without being blocked.

Due to its approach to color and brightness, OLEDs have great contrast ratios. There’s no need to block a backlight, so there’s no worries about light bleeding through. Blacks are very black, and colors look great. OLEDs can also strobe, or flash off and on quickly to lower persistence. They can also use a trick called rolling scan.This turns blocks of the screen on and off one at a time, from top to bottom in a roll. This is all done as the image is sent to the screen, which cuts down on persistence blur a lot. This is why every major VR headset that can afford it uses OLED panels today.

Unfortunately, that’s where the advantages of OLED end. Refresh rates of OLED panels have never surpassed about 90Hz. And they’re quite expensive. A large part of that $1,000 iPhone X price is due to its OLED display. The current molecules used in OLEDs also degrade relatively quickly over time, especially those used for the color blue(opens in new tab), making the screen less and less bright.

OLEDs were also supposed to use less power than LCDs, but newer, giant OLED molecules that take less voltage to turn on have yet to appear. And while molecules covering the colors of the P3 HDR gamut are out today, those covering the larger BT.2020 gamut have yet to be found commercially. So OLEDs, while once promising and seemingly the future, have yet to live up to that promise.

There are plenty of new and confusing terms facing TV shoppers today, but when it comes down to the screen technology itself, there are only two: Nearly every TV sold today is either LCD or OLED.

The biggest between the two is in how they work. With OLED, each pixel provides its own illumination so there"s no separate backlight. With an LCD TV, all of the pixels are illuminated by an LED backlight. That difference leads to all kinds of picture quality effects, some of which favor LCD, but most of which benefit OLED.

LCDs are made by a number of companies across Asia. All current OLED TVs are built by LG Display, though companies like Sony and Vizio buy OLED panels from LG and then use their own electronics and aesthetic design.

So which one is better? Read on for their strengths and weaknesses. In general we"ll be comparing OLED to the best (read: most expensive) LCD has to offer, mainly because there"s no such thing as a cheap OLED TV (yet).

The better LCDs have local dimming, where parts of the screen can dim independently of others. This isn"t quite as good as per-pixel control because the black areas still aren"t absolutely black, but it"s better than nothing. The best LCDs have full-array local dimming, which provides even finer control over the contrast of what"s onscreen -- but even they can suffer from "blooming," where a bright area spoils the black of an adjacent dark area.

One of the main downsides of LCD TVs is a change in picture quality if you sit away from dead center (as in, off to the sides). How much this matters to you certainly depends on your seating arrangement, but also on how much you love your loved ones.

A few LCDs use in-plane switching (IPS) panels, which have better off-axis picture quality than other kinds of LCDs, but don"t look as good as other LCDs straight on (primarily due to a lower contrast ratio).

OLED doesn"t have the off-axis issue LCDs have; its image looks basically the same, even from extreme angles. So if you have a wide seating area, OLED is the better option.

Nearly all current TVs are HDR compatible, but that"s not the entire story. Just because a TV claims HDR compatibility doesn"t mean it can accurately display HDR content. All OLED TVs have the dynamic range to take advantage of HDR, but lower-priced LCDs, especially those without local-dimming backlights, do not. So if you want to see HDR content it all its dynamic, vibrant beauty, go for OLED or an LCD with local dimming.

In our tests comparing the best new OLED and LCD TVs with HDR games and movies, OLED usually looks better. Its superior contrast and lack of blooming win the day despite LCD"s brightness advantage. In other words LCD TVs can get brighter, especially in full-screen bright scenes and HDR highlights, but none of them can control that illumination as precisely as an OLED TV.

OLED"s energy consumption is directly related to screen brightness. The brighter the screen, the more power it draws. It even varies with content. A dark movie will require less power than a hockey game or ski competition.

The energy consumption of LCD varies depending on the backlight setting. The lower the backlight, the lower the power consumption. A basic LED LCD with its backlight set low will draw less power than OLED.

LG has said their OLED TVs have a lifespan of 100,000 hours to half brightness, a figure that"s similar to LED LCDs. Generally speaking, all modern TVs are quite reliable.

Does that mean your new LCD or OLED will last for several decades like your parent"s last CRT (like the one pictured). Probably not, but then, why would you want it to? A 42-inch flat panel cost $14,000 in the late 90"s, and now a 65-inch TV with more than 16x the resolution and a million times better contrast ratio costs $1,400. Which is to say, by the time you"ll want/need to replace it, there will be something even better than what"s available now, for less money.

OLED TVs are available in sizes from 48 to 88 inches, but LCD TVs come in smaller and larger sizes than that -- with many more choices in between -- so LCD wins. At the high end of the size scale, however, the biggest "TVs" don"t use either technology.

You can get 4K resolution, 50-inch LCDs for around $400 -- or half that on sale. It"s going to be a long time before OLEDs are that price, but they have come down considerably.

LCD dominates the market because it"s cheap to manufacture and delivers good enough picture quality for just about everybody. But according to reviews at CNET and elsewhere, OLED wins for overall picture quality, largely due to the incredible contrast ratio. The price difference isn"t as severe as it used to be, and in the mid- to high-end of the market, there are lots of options.

Through improvements in LCD parts and materials, monitor weight has been reduced over earlier models, making it easier to transport and install the display.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey