sunlight readable tft display factory

This 128x160 resolution LCD TFT is equipped with a powerful backlight, providing visibility in bright lighting conditions including the direct sun. The sunlight readable display comes with 3/4-wire SPI interface and offers a 6:00 optimal view. This 2.8V Liquid Crystal Display has a built-in ILI9163V controller, FFC connection, is RoHS compliant and does not come with a touchscreen.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

WF43VSIAEDNN0 is a sunlight readable TFT LCD module with high brightness of 1000 cd/m2 (typical value). WF43VSIAEDNN0 is a color TFT LCD with WQVGA 480x272 resolution, diagonal size 4.3 inch. This TFT model is built in with ST7282 driver IC. WF43VSIAEDNN0 supports 24-bit RGB interface; it’s available for Resistive Touch Screen (RTP) and Projected Capacitive Touch Screen (CTP) optional. WF43VSIAEDNN0 is an alternative item to replace WF43HSIAEDNNB which adopted CPT (Chunghwa Picture Tubes Ltd) TFT panel.

The supply voltage for logic (VCC) of WF43VSIAEDNN0 is from 3.1V to 3.5V, typical value 3.3V. It is featured with Glare surface panel, View Direction 12 o"clock, Gray scale inversion 6 o"clock, and aspect ratio 16:9.. It can be operating at temperatures from -20℃ to +70 ℃ and storage temperatures from -30 to +80 ℃. Winstar’s sunlight readable TFT LCD is perfect for outdoor measuring equipment, industrial measuring equipment, testing equipment, measuring tools, measuring instruments, etc.

Sunlight readable TFT LCD display: By high brightness backlight, we can make sunlight readable LCD modules such as our 2.0inch 240x320 1000nits, 3.34 inch round display 320x320 750nits, 3.5inch IPS 320x480 2000nits, 3.5inch 320x240 600nits, 4.3inch 480x272 800nits, 5.0inch 800x480 1000nits, 7.0inch 800x480 and 1024x600 1000nits, 10.1inch wide temperature LCD display 1280x800 IPS 1000nits.... For other sizes of sunlight readable screen, we can custom made high brightness sun readable LCD displays for you too. As a LCD factory, we can produce qualified sunlight readable touch screens and our sunlight readable LCD prices are competitive in the market. Feel free to contact us.

Is there a demo of this display to prove that it actually works? Because leaving out the serial interface seems like it might have been a mistake made by the designers. I just want to make sure that this module actually functions.

Sunlight readable Digital Displays – CDS has the widest range and variety of hibrite sunlight readable LCD display solutions and industrial hi-brite LCD TFT displays for applications in direct sunlight.

There are different hibrite TFT panel technologies available to achieve sunlight readability in environments with very bright ambient environments, with high brightness up to 5000 nits! The most common way is to upgrade the backlight to dramatically increase brightness with our high-quality LED backlights. However, we also have factory manufactured super high bright panels featuring optical bonding technology in order to make our TFT panels sunlight readable.

Although high brightness displays will generate more heat and use more power than a traditional LCD ours utilise the latest low power high bright LEDs to keep power consumption to a minimum.

To get a clear image under the sunlight, the high brightness displays should be over 700cd/㎡ +,with good contrast and ideally 1000cd/m² +. This is because the illumination of ambient daylight is around 30,000㎡(107,600 LUX). Our high brightness LCDs are possible up to 2,500㎡ and designed with proprietary technologies and produced at our well-equipped factory.

Our high brightness display products have been installed in locations around the world for the outdoor applications such as outdoor KIOSK, Fuel pumps, Vending machine, Outdoor ATM, Military, Marine etc.

Alternatively, Optical Bonding is a great technology for sunlight readability on our high brightness displays. Optical Bonding is a process in which an optical gel is bonded between your LCD and a cover glass or touchscreen. The gel behind the glass stops any condensation, strengthens the front glass, and also improves sunlight readability. It also keeps power and heat down as does not affect the backlight in any way.

Our displays outperform commercial products that washout in sunlit conditions. Superior quality and readability make these displays an ideal solution for factory automation, marine/mobile and process control applications.

Our proprietary backlight technology was developed for high brightness displays and Outdoor readable Display Monitors requiring a luminance level of at least 700 nits (cd/m²) as required for outside viewing.

Other improvements include significantly reduced power consumption, increased reliability and extended lifetime of the Sunlight readable Digital Displays and high brightness display systems.

CDSSunlight readable Digital Displays alsoinclude ….… High brightness LED Displays, square Displays, waterproof marine Displays, widescreen Displays, display showcases, curved touch screen Displays, large square Displays, IP65 and IP66 Displays, Digital Display screens, square computer Displays, Industrial LCD Displays, largest ultra-wide Display, daylight readable Displays, touch overlay for Displays, ultra-wide touch screen Display, large capacitive touchscreen Displays, square LCD Displays, kiosk screens, infrared touch screen Display, clear touch screen Displays, weather proof IP66 Displays, marine LCD Displays, interactive touchscreen Display, one glass solutions, embedded Displays, USB touchscreen Displays, low power LCD Displays, kiosk touch Displays, high brightness Displays, LCD Display, outdoor Display screens, multi-touch Display, Dynascan Displays, dual touch screen Displays, outdoor digital screen displays, square HDMI Display, touchscreen overlays for Displays, optical bonding Displays as well as optically bonded Displays, water resistant touch screen Displays, glass touch screen Displays, waterproof touch screen Displays, mini USB Display touch, video wall display Displays, high bright TFTs, high bright TFT LCD, high bright TFT Displays, high brightness Displays, sunlight readable TFT LCD Displays, High Bright LCDs, High Brightness TFT modules, high bright TFT-LCD, enhanced brightness Displays, anti-reflective, anti-glare coatings, high brightness TFT LCD modules, High Bright TFTs, high brightness TFT-LCD, High Brightness TFT Displays, LED backlights, high ambient brightness, high brightness TFT Displays, sunlight readable displays, resistive touch panel, capacitive touch panel, high brightness TFT Display, high back lighting sunlight viewable TFT Display, 10.1″ high bright colour PCAP TFT LCD Display, 5.7″ high bright TFT Display module, full colour TFT display module, high screen luminance, ultra-bright TFT LCD, low cost high end TFT modules, ultra-bright 1300nit backlights, optical bonded anti-reflective overlays, sunlight readability, and advertising Displays LCD.

The diagonal size of RFE430W-AWH-DNN is 4.3", and it’s a sunlight readable display with resolution of 480x272 dot. With brightness of 1000 cd/㎡ (nits), contrast ratio (typical value) 800:1, and viewing angle 80/80/80/80 degree, this model RFE430W-AWH-DNN sunlight readable TFT LCD Display is suitable for indoors and outdoors applications. The operating and storage temperature both range from -30℃~+80℃.

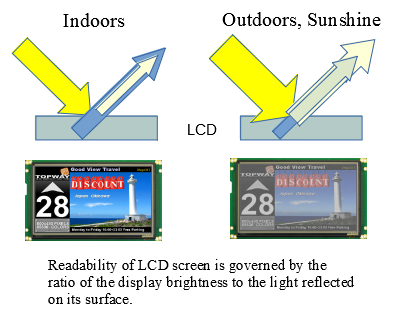

There are more and more TFT displays used in outdoor applications, such as automobile display, digital signage and kiosks. High ambient light in outdoor environment often causes wash-out image and renders the screen not readable. Readability & sustainability of TFT display under direct sunlight is becoming vital. Topway Display has been developing sunlight readable LCD display solution for years. The company understands the ins and outs of sunlight readable TFT LCD.

For an LCD to be readable in outdoor environment with very bright ambient light, the LCD screen’s brightness needs to exceed the intensity of light that is reflected from the display surface. To be comfortably viewed by human eyes, the LCD’s brightness needs to exceed its reflected light by a factor of 2.5 at minimum. Naturally, to make an LCD sunlight readable, we can work on two areas, increasing brightness or reducing reflectance.

On a clear day in direct sunlight, the ambient brightness is about 6000 cd/m2. And a typical TFT LCD with touch screen reflects about 14% of ambient light, which is around 840 cd/m2. These days, most LCD displays use LED backlight as light source. It is not too difficult to increase an LCD’s brightness to 800 ~ 1000 Nits, to overpower the bright reflected sunlight. Thus, you have a sunlight readable TFT LCD.

However, this method requires more backlight LEDs and/or higher driving current. The drawbacks are high power consumption, more heat dissipation, increased product size and shorter LED backlight lifespan. Apparently, increasing backlight to make TFT LCD sunlight-readable is not a very good solution.

Transflective TFT LCD is a TFT LCD with both transmissive and reflective characteristics. A partially reflective mirror layer is added between LCD and backlight. This change turns part of the reflected ambient light into LCD’s light source, increasing the TFT display’s brightness. However, transflective TFT LCD is more expensive than transmissive one. At the same time, the partially reflective mirror layer will block some of the backlight, making it not ideal in indoor or low ambient light environment.

The total reflectance on a TFT LCD with touch panel is the sum of reflected light on any interface where two materials meet. As an example, between polarizer and display glass, the difference in index of refractions for the two materials is very small, around 0.1. So the reflected light on this interface is only 0.1%. As Fresnel’s equation points out, we should focus reflection reduction on air interfaces. For air, its index of refraction is 1; for glass, it is 1.5. And that results in a reflectance of 4.5%. Therefore, the three air interfaces contribute majority of TFT LCD’s reflectance, at about 13%.

For food industry application, shattered glass is a serious problem. An LCD screen with external film solves this issue nicely. As for automotive applications, in an accident, broken LCD with top AR film won’t produce sharp edge glass that could harms auto occupant. Nevertheless, a top film always reduces TFT LCD’s surface hardness. And it is susceptible to scratches. On the other hand, AR coating retains LCD’s hardness and touch performance. But it comes with a bigger price tag.

Another quick and easy way to tackle reflectance is to affix a linear polarizer on the top of TFT screen. When ambient light gets to the top polarizer, only half of the light passes through. Which results in reflection light cutting to half. This is a very low cost way to increase TFT LCD’s contrast, such that making it more sunlight readable.

Laminating a circular polarizer in TFT LCD will get rid of a lot of reflectance. That is because when ambient light passes through circular polarizer it gets circularly polarized. And when it is reflected, the polarization direction flips by 180 degrees. So when reflected light comes back to the circular polarizer, nothing goes through to viewer’s eyes.

This method is very effective for an LCD display with resistive touch panel. We know resistive touch LCD has two air gaps: air gap between two ITO layers and air gap between touch panel and LCD display. Reflectance caused by the two air gaps is very high. Applying circular polarizer blocks off most of the reflected light, and makes the LCD display sunlight readable.

The disadvantage of such solution is its cost. Since we need not only a circular polarizer, but also a retarder film on the top of LCD display, making sure light originates from within LCD is not blocked by external circular polarizer.

Add AR films on both interfaces of internal air gap. The add-ons can reduce this area’s reflection from 8.5% to 2%. And since the AR films are not outside facing, they are much cheaper than the one used outside. Keeping the air gap also retains the ease of service, in case either touch panel or LCD display needs to be repaired.

The most effective way is to eliminate air gap totally, by using optical bonding. In plain language, we fill air gap with special optical adhesive, to smooth out the area’s refraction index differences. Such that reflectance caused by internal air gap drops from 8.5% to 0.5%. Optical bonding is expensive but effective way to improve TFT LCD sunlight readability. It enhances durability and resistance to impact. Moreover, no air gap means no moisture condensation and fogging.

There are many ways to make TFT LCDsunlight readable. They all have their own pros and cons. With 20+ years" LCD design and manufacturing experience, Topway knows how to create the best sunlight readable TFT LCD for challenging environments. Leave us a message and let"s start the conversation of creating suitable sunlight readable TFT LCD for your project.

When display devices are brought outside, oftentimes they face the brightness of sunlight or any other form of high ambient light sources reflecting off of and overwhelming the LED backlight’s image.

With the growth of the LCD panel industry as a whole, it has become more important than ever to prevent the sun’s wash out of displays used outdoors, such as automobile displays, digital signage, and public kiosks. Hence, the sunlight readable display was invented.

One solution would be to increase the luminance of the TFT LCD monitor’s LED backlight to overpower the bright sunlight and eliminate glare. On average, TFT LCD screens have a brightness of about 250 to 450 Nits, but when this is increased to about 800 to 1000 (1000 is the most common) Nits, the device becomes a high bright LCDand a sunlight readable display.

Since many of today’s TFT LCD display devices have shifted to touchscreens, the touch panels on the surface of LCD screens already block a small percentage of backlighting, decreasing the surface brightness and making it so that the sunlight can even more easily wash out the display. Resistive touch panels use two transparent layers above the glass substrate, but the transparent layers can still block up to 5% of the light.

In order to optimize the high brightness of the backlight, a different type of touchscreen can be used: the capacitive touchscreen. Though it is more expensive than the resistive touch screen, this technology is more ideal for sunlight readable displays than the resistive due to its usage of a thinner film or even in-cell technologies rather than two layers above the glass of the display, and therefore, light can pass more efficiently.

However, with this method comes a list of potential problems. Firstly, high brightness displays result in much greater power consumption and shorter battery life. In order to shed more light, more power will be needed which can also consequently result in device overheating which can also shorten battery life. If the backlight’s power is increased, the LED’s half-life may also be reduced.

While in bright exterior light settings, these devices reduce eye strain as the user attempts to view the image on screen, the brightness of the display itself can also cause eye strain, seen as the brightness may overwhelm your eyes. Many devices allow the user to adjust brightness, so this concern is oftentimes not too severe.

A recent technology falling into the sunlight readable display category is the transflective TFT LCD, coming from a combination of the word transmissive and reflective. By using a transflective polarizer, a significant percentage of sunlight is reflected away from the screen to aid in the reduction of wash out. This optical layer is known as the transflector.

In transflective TFT LCDs, sunlight can reflect off the display but can also pass through the TFT cell layer and be reflected back out off a somewhat transparent rear reflector in front of the backlight, illuminating the display without as much demand and power usage from the transmissive nature of the backlight. This addresses both the issues of wash out and the disadvantages of high brightness TFT LCDs in high ambient light environments. Because of its transmissive and reflective modes, this type of device is very useful for devices that will be used outdoors but also indoors.

In addition to adjustments to the internal mechanics of LCDs, it is possible to make devices more sunlight-readable using surface treatments. The most common are anti-reflective (A/R) films/coatings and anti-glare processing.

When anti-glare is used, reflected light is fragmented. Using a rough surface as opposed to a smooth one, anti-glare treatments can reduce the reflection’s disruption of the actual image of the display.

Often paired with other methods of creating sunlight readable displays is optical bonding. By gluing the glass of a display to the TFT LCD cells beneath it, optical bonding eliminates the air gap that traditional LCD displays have in them using an optical grade adhesive.

With this contrast ratio improvement, optical bonding addresses the root issue with unreadable outdoor displays: the contrast. Though an increase in brightness can improve contrast, by fixing the contrast itself, LCD display images in outdoor environments will not be as washed out and will require less power consumption.

Besides the visual display advantages that optical bonding provides, this adhesive improves the display in many other ways. The first being durability, optical bonding eliminates the air gap within the device and replaces it with a hardened adhesive that can act as a shock absorber.

Touch screens with optical bonding gain, accuracy in where the point of contact is between the touch and screen. What is known as parallax, the refraction angle of light, can make it seem that the point of contact and the actual point on the display are different. When the adhesive is used, this refraction is minimized, if not reduced.

Compiling the various methods of improving LCD screens for sunlight readability, these devices can be optimized in high ambient light settings. An anti-glare coating is applied to the surface of the glass and anti-reflective coatings are applied to both the front and back. The transflector is also used in front of the backlight. These features can result in 1000 Nit or more display lighting, without the excessive power consumption and heat production through a high brightness backlight, consequently allowing for a longer lasting and better performing LCD

Unfortunately, the process of building a reflector inside TFT LCD is complicated and transflective TFT LCD is normally several times higher cost compared with normal transmissive TFT LCD.

To further improve and enhance the qualities of the LCD, LED and cold cathode fluorescent lamp (CCFL) backlights are used. Both these create bright displays, but the LED specifically can do so without as much power consumption and heat generation as compared to the CCFL option. Optical bonding is also applied in order to improve display contrast, leading to a more efficient and better quality sunlight readable display.

When display devices are brought outside, oftentimes they face the brightness of sunlight or any other form of high ambient light sources reflecting off of and overwhelming the LED backlight’s image.

With the growth of the LCD panel industry as a whole, it has become more important than ever to prevent the sun’s wash out of displays used outdoors, such as automobile displays, digital signage, and public kiosks. Hence, the sunlight readable display was invented.

One solution would be to increase the luminance of the TFT LCD monitor’s LED backlight to overpower the bright sunlight and eliminate glare. On average, TFT LCD screens have a brightness of about 250 to 450 Nits, but when this is increased to about 800 to 1000 (1000 is the most common) Nits, the device becomes a high bright LCDand a sunlight readable display.

Since many of today’s TFT LCD display devices have shifted to touchscreens, the touch panels on the surface of LCD screens already block a small percentage of backlighting, decreasing the surface brightness and making it so that the sunlight can even more easily wash out the display. Resistive touch panels use two transparent layers above the glass substrate, but the transparent layers can still block up to 5% of the light.

In order to optimize the high brightness of the backlight, a different type of touchscreen can be used: the capacitive touchscreen. Though it is more expensive than the resistive touch screen, this technology is more ideal for sunlight readable displays than the resistive due to its usage of a thinner film or even in-cell technologies rather than two layers above the glass of the display, and therefore, light can pass more efficiently.

However, with this method comes a list of potential problems. Firstly, high brightness displays result in much greater power consumption and shorter battery life. In order to shed more light, more power will be needed which can also consequently result in device overheating which can also shorten battery life. If the backlight’s power is increased, the LED’s half-life may also be reduced.

While in bright exterior light settings, these devices reduce eye strain as the user attempts to view the image on screen, the brightness of the display itself can also cause eye strain, seen as the brightness may overwhelm your eyes. Many devices allow the user to adjust brightness, so this concern is oftentimes not too severe.

A recent technology falling into the sunlight readable display category is the transflective TFT LCD, coming from a combination of the word transmissive and reflective. By using a transflective polarizer, a significant percentage of sunlight is reflected away from the screen to aid in the reduction of wash out. This optical layer is known as the transflector.

In transflective TFT LCDs, sunlight can reflect off the display but can also pass through the TFT cell layer and be reflected back out off a somewhat transparent rear reflector in front of the backlight, illuminating the display without as much demand and power usage from the transmissive nature of the backlight. This addresses both the issues of wash out and the disadvantages of high brightness TFT LCDs in high ambient light environments. Because of its transmissive and reflective modes, this type of device is very useful for devices that will be used outdoors but also indoors.

In addition to adjustments to the internal mechanics of LCDs, it is possible to make devices more sunlight-readable using surface treatments. The most common are anti-reflective (A/R) films/coatings and anti-glare processing.

When anti-glare is used, reflected light is fragmented. Using a rough surface as opposed to a smooth one, anti-glare treatments can reduce the reflection’s disruption of the actual image of the display.

Often paired with other methods of creating sunlight readable displays is optical bonding. By gluing the glass of a display to the TFT LCD cells beneath it, optical bonding eliminates the air gap that traditional LCD displays have in them using an optical grade adhesive.

With this contrast ratio improvement, optical bonding addresses the root issue with unreadable outdoor displays: the contrast. Though an increase in brightness can improve contrast, by fixing the contrast itself, LCD display images in outdoor environments will not be as washed out and will require less power consumption.

Besides the visual display advantages that optical bonding provides, this adhesive improves the display in many other ways. The first being durability, optical bonding eliminates the air gap within the device and replaces it with a hardened adhesive that can act as a shock absorber.

Touch screens with optical bonding gain, accuracy in where the point of contact is between the touch and screen. What is known as parallax, the refraction angle of light, can make it seem that the point of contact and the actual point on the display are different. When the adhesive is used, this refraction is minimized, if not reduced.

Compiling the various methods of improving LCD screens for sunlight readability, these devices can be optimized in high ambient light settings. An anti-glare coating is applied to the surface of the glass and anti-reflective coatings are applied to both the front and back. The transflector is also used in front of the backlight. These features can result in 1000 Nit or more display lighting, without the excessive power consumption and heat production through a high brightness backlight, consequently allowing for a longer lasting and better performing LCD

Unfortunately, the process of building a reflector inside TFT LCD is complicated and transflective TFT LCD is normally several times higher cost compared with normal transmissive TFT LCD.

To further improve and enhance the qualities of the LCD, LED and cold cathode fluorescent lamp (CCFL) backlights are used. Both these create bright displays, but the LED specifically can do so without as much power consumption and heat generation as compared to the CCFL option. Optical bonding is also applied in order to improve display contrast, leading to a more efficient and better quality sunlight readable display.

A wide variety of 4 inch sunlight readable lcd options are available to you, You can also choose from original manufacturer, odm and agency 4 inch sunlight readable lcd,As well as from tft, ips, and tn.

You need to reach the top manufacturer and provider of high brightness LCD displays. They are available in a variety of sizes and designs that you can get from the comfort of home. Leadtek Display, the professional display service provider based in China, offers you a broad range of high brightness LCD displays that are easy to use and come with a number of added features and benefits. Our broad range of such display modules is provided with precise information about their uses in different industrial domains. Choosing the best one depends on your requirement and industrial uses. They are offered with precise information about them to help you in finding something latest and unique. Our prices are competitive and backed by discounts; while you can get them delivered on time and in secure way to your address. Our broad ranges of displays are used largely in different industries and for different purposes. They are delivered with precise information about them, technical points and features along with a user guide.

Products»All Products»Power & UPS»Batteries & Ultracapacitors»Standard DC-DC Power»Smart DC-DC Power»Smart Battery Chargers»Galvanically Isolated Power Supplies»24V Output Supplies»Ultracapacitor Chargers»Adjustable Output Power Supplies»Universal Chargers»Uninterruptible Power Supplies»Embedded Boards»I/O & Communication»Embedded CAN bus Modules»Embedded Ethernet Switches»Embedded Digital IO Modules»Embedded Analog IO Modules»Embedded Serial IO Modules»PCIe Mini Cards»Embedded Power Supplies»Standard Embedded Power»Smart Embedded Power»PC/104 Power Supplies»Embedded UPS Modules»Embedded Motherboards»PC/104 Motherboards»ETX Motherboards»COM Express Motherboards»EPIC Motherboards»EBX Motherboards»Mini-ITX Motherboards»Micro-ATX Motherboards»Industrial ATX Motherboards»Embedded GPS Modules»GPS Receiver Modules»Embedded GPS Antennas»CPU Boards & SBC»PC/104 SBC»EPIC SBC»ETX SBC»EBX SBC»Mini-ITX SBC»ARM CPU Modules»Micro-ATX SBC»Embedded ATX SBC»Com Express SBC»Embedded Ultracapacitor Modules»Embedded Battery Modules»Embedded Video Cards»Systems»Fanless Box PC»Wide Temperature»Industrial Automation Computers»Rugged Vehicle Computers»Railway Computers»Vehicle Tracking Systems»Industrial Rackmount Computers»Wide Temperature Systems»Digital Displays»Marine Monitors»Rugged LCD Displays»Wide Temperature LCD Displays»Waterproof LCD Panels»Advertising LCD Displays»Stretched Bar LCD»Sunlight Readable LCD Displays»Public Transportation LCD Displays»Railway LCD Displays»Outdoor LCD Displays»High Brightness LCD Displays»Extended Temperature LCD Displays»Industrial Monitors»Panel Computing»Marine Panel PC»Infotainment Panel PC»Wide Temperature Panel PC»HMI Panel PC»Modular Panel PC»Mobile Computing»Rugged Tablets»Rugged Windows Tablets»Rugged Android Tablets»Rugged PDA»Antennas»GPS Antennas»External GPS Antennas»Passive GPS Antennas»Active GPS Antennas»Marine GPS Antennas»Internal GPS Antennas»GNSS Antennas»GLONASS Antennas»Multi-Band Antennas»GPS-GLONASS Antennas»Iridium Antennas»GPS & RF Signal Distribution»GPS Amplifiers»Low Noise Amplifiers»GPS Receivers»Marine GPS Receivers»GPS Attenuators»GPS Combiners»GPS Splitters»Active GPS Splitters»Military GPS Splitters»Rackmount GPS Splitters»Passive GPS Splitters»Repeaters»GPS Repeaters»GLONASS Repeaters»GPS Filters»Enclosures & Chassis»PC/104 Chassis»Rugged Mini-ITX Cases»EPIC Enclosures»EBX Enclosures»Memory & Storage»Memory»Flash Storage»Industrial SSD»SATA Disk On Modules»Industrial Micro SD Cards»Industrial SD Cards»Industrial CompactFlash Cards»Sensors»Industrial Networking»Manufactured by Tri-M»Power & UPS»Standard Power Supplies»HE104: 60 Watt»HE104-DX: 60 Watt»HE104-75W: 75 Watt»HE104+DX: 108 Watt»HE-HP: 100 Watt»Smart Power Supplies (PowerOS)»HESC-SERD: 60 Watt»HESC104+: 108 Watt»HPS3512: 203 Watt»HPSP-XYZ: 240W Programmable»V12SC-SER[-UPS]»TPS1000: 35 Watt, 42 Watt»TPSi1075: 75 Watt, Isolated»TPSi1085: 85 Watt, Isolated»HPSC104-SER: 160 Watt»HESC104: 60 Watt»TPS1035»TPC1000»HPS3524»Smart UPS (PowerOS)»TUP1000: Ultracapacitor UPS»V5SC-SER-UPS: NiMh Battery UPS»UltraUPS»V12SC-SER[-UPS]»Ultra Capacitor Packs»TBP4xxx»Battery Backup Packs»BAT-NiMh45»BAT104-NiMh»BAT104-NiCd»BAT-SLA(25/45)»UltraUPS»Heavy Duty Transient Stopper»CPU Modules»I/O & Communication»Input / Output»IO104-60IN: PC104 I/O Board»IR104 PC/104 Relay Module»Communication»TCB1000 PC/104 Com Board»FlexCom104-GPS»Enclosures»VersaTainer: PC104 & EBX»CanTainer: PC104»FlexTainer: EPIC, MITX, EBX»GPS & Networking»GPS & Networking Boards»FlexCom104-GPS»Antennas»Mighty Mouse: Small GPS Antenna»Micro Mouse: Micro GPS Antenna»Big Brother»Re-Radiators»Super-Radiator»Xtreme-Radiator»Vehicle GPS Repeater»Complete System Solutions»HECS1000 System»UltraUPS Complete Backup Solution»Support Products & Accessories»PC104-T AC Termination Modules»Extract104»TS-I2C Temperature Sensor»DA104»VSX-2812 Video Modules»ISA104X1»Postcode104»Legacy Products»Distributed by Tri-M»Diamond Systems»Single Board Computers»Aurora PC/104 SBC»Helios PC/104 SBC»Neptune EPIC SBC»Pluto ETX SBC»Hercules III EBX SBC»IEI»IEI Mobile»MicroMax Computer Intelligence»San Jose Technology (SANAV)»GNSS Repeaters»RK-306»RK-106»Innodisk»GPS Networking»Litemax»Spanpixel»Durapixel»Navpixel»Aaeon Electronics»Systems»Fanless Embedded Computers»Entry-Level Box PC»ICOP Technology»ICOP-2811»VDX2-6554»VEX-6254»VSX-2812S»86Duino Enjoy Desktop 3D Printer»MPLSelector Guides»Power Selector Guide»Backup Power SelectorServices»Conformal Coating»HumiSeal 1B31»Laser Engraving & EtchingTri-M Rugged»PowerOS»Mining Applications»Mining Application Story»Rail & ITS Applications»Automation & Manufacturing»Mil-Aero Defence & Aerospace»Aerospace Application StorySupportAbout Us»About Us»Privacy PolicywebstoreTriple Programmable PSUQuote Request

NMLCD-05TSFis a transflective type TFT-LCD module which is sunlight readable. This module is composed of LCD panel, driver IC, and LED backlight. The resolution is 480×480.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey