help point phone with lcd panel supplier

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

LED video wall solution with advanced video wall processing, off-board electronics, front serviceable cabinets and outstanding image quality available in 0.9mm pixel pitch

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Advanced LED video wall with MicroLED models in 0.6, 0.7 and 0.9mm pixel pitches, and 1.2mm pixel pitch standard LED; with powerful processing, proprietary alignment technology and off-board electronics.

LED video wall solution with advanced video wall processing, off-board electronics, front serviceable cabinets and outstanding image quality available in 0.9mm pixel pitch

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

Android System, LG original IPS Panel, Support in Double-sided Display / Different Content, Ultra-thin 21mm, ultra-light 16.5kg, 450/800 Nits, Support Remote Audio and Video Release, Support Remote Audio and Video Release

Industrial Display Systems provide a wide range of reliable displays from 5.7" to 55" including LCD displays, touch screen panels, outdoor displays and digital signage displays, and a series of industrial monitors including open frame monitors and panel mount monitors, which work perfectly with embedded boards and systems to fulfill various application needs.

(8 February, 2018) – Total shipments of mobile phone displays, including thin-film transistor liquid crystal display (TFT LCD) and active matrix organic light-emitting diode (AMOLED) panels, reached 2.01 billion units in 2017, up 3 percent from 2016, according to preliminary estimate from business information provider

In the growing mobile phone display market, shipments of low-temperature-poly-silicon (LTPS) TFT LCD panels, which realize high-resolution images, increased by 21 percent to 620 million units in 2017 compared to the previous year. Shipments of amorphous silicon (a-Si) TFT LCD mobile phone panels declined 4 percent to 979 million units during the same period. Even though shipments of AMOLED panels jumped in the second half of 2017 thanks to the launch of the iPhone X, combined with the weak demand in the first half, its shipments were up just 3 percent to 402 million units in 2017.

In the smartphone-use LTPS TFT LCD market, Tianma, a leading small and medium panel supplier in China, has shown significant growth, expanding its shipments to Chinese smartphone set brands, such as Huawei and Xiaomi. In 2017, Tianma shipped 105 million LTPS TFT LCD panels for smartphones, almost double its shipments in 2016, with a market share of 17 percent, up 6 percentage points from 2016. It ranked the second largest LTPS TFT LCD supplier for smartphones in 2017, taking over LG Display with 16 percent, down 4 percentage points, and Sharp with 13 percent, down 1 percentage point. In 2017, Japan Display continued its market leader position but shed its share by 10 percentage points to 26 percent in 2017, according to the latest

“LTPS TFT is a key technology to produce high-resolution displays for smartphones, and experience is required to optimize highly complex LTPS manufacturing process in each production fab. In terms of experience, Japanese and South Korean panel makers have a competitive advantage compared to Chinese makers,” said

. “However, Chinese LCD makers, such as Tianma and BOE, are catching up LTPS technology fast enough to support high demand from Chinese smartphone set makers.”

by IHS Markit contains quarterly updates of smartphone display shipments and revenue by application, size, resolution and technology. It also provides supply chain information between display and set makers, as well as monthly smartphone display shipment and pricing information.

The technical storage or access that is used exclusively for anonymous statistical purposes. Without a subpoena, voluntary compliance on the part of your Internet Service Provider, or additional records from a third party, information stored or retrieved for this purpose alone cannot usually be used to identify you.

In recent years, smartphone displays have developed far more acronyms than ever before with each different one featuring a different kind of technology. AMOLED, LCD, LED, IPS, TFT, PLS, LTPS, LTPO...the list continues to grow.

As if the different available technologies weren"t enough, component and smartphone manufacturers adopt more and more glorified names like "Super Retina XDR" and "Dynamic AMOLED", which end up increasing the potential for confusion among consumers. So let"s take a look at some of these terms used in smartphone specification sheets and decipher them.

There are many display types used in smartphones: LCD, OLED, AMOLED, Super AMOLED, TFT, IPS and a few others that are less frequently found on smartphones nowadays, like TFT-LCD. One of the most frequently found on mid-to-high range phones now is IPS-LCD. But what do these all mean?

LCD means Liquid Crystal Display, and its name refers to the array of liquid crystals illuminated by a backlight, and their ubiquity and relatively low cost make them a popular choice for smartphones and many other devices.

LCDs also tend to perform quite well in direct sunlight, as the entire display is illuminated from behind, but does suffer from potentially less accurate colour representation than displays that don"t require a backlight.

Within smartphones, you have both TFT and IPS displays. TFT stands for Thin Film Transistor, an advanced version of LCD that uses an active matrix (like the AM in AMOLED). Active matrix means that each pixel is attached to a transistor and capacitor individually.

The main advantage of TFT is its relatively low production cost and increased contrast when compared to traditional LCDs. The disadvantage of TFT LCDs is higher energy demands than some other LCDs, less impressive viewing angles and colour reproduction. It"s for these reasons, and falling costs of alternative options, that TFTs are not commonly used in smartphones anymore.Affiliate offer

IPS technology (In-Plane Switching) solves the problem that the first generation of LCD displays experience, which adopts the TN (Twisted Nematic) technique: where colour distortion occurs when you view the display from the side - an effect that continues to crop up on cheaper smartphones and tablets.

The PLS (Plane to Line Switching) standard uses an acronym that is very similar to that of IPS, and is it any wonder that its basic operation is also similar in nature? The technology, developed by Samsung Display, has the same characteristics as IPS displays - good colour reproduction and viewing angles, but a lower contrast level compared to OLED and LCD/VA displays.

According to Samsung Display, PLS panels have a lower production cost, higher brightness rates, and even superior viewing angles when compared to their rival, LG Display"s IPS panels. Ultimately, whether a PLS or IPS panel is used, it boils down to the choice of the component supplier.

This is a very common question after "LED" TVs were launched, with the short answer simply being LCD. The technology used in a LED display is liquid crystal, the difference being LEDs generating the backlight.

One of the highlights from TV makers at the CES 2021 tradeshow, mini-LED technology seemed far removed from mobile devices until Apple announced the 2021 iPad Pro. As the name implies, the technique is based on the miniaturization of the LEDs that form the backlight of the screen — which still uses an LCD panel.

Despite the improvement in terms of contrast (and potentially brightness) over traditional LCD/LED displays, LCD/mini-LEDs still divide the screen into brightness zones — over 2,500 in the case of the iPad and 2021 "QNED" TVs from LG — compared to dozens or hundreds of zones in previous-generation FALD (full-array local dimming) displays, on which the LEDs are behind the LCD panel instead of the edges.

However, for even greater contrast control, done individually at each point on the screen, it is necessary to go to panels equipped with microLED technologies – still cost-prohibitive in 2021 – or OLED, which until recently were manufactured on a large scale only in sizes for smartphones or televisions.Affiliate offer

AMOLED stands for Active Matrix Organic Light-Emitting Diode. While this may sound complicated it actually isn"t. We already encountered the active matrix in TFT LCD technology, and OLED is simply a term for another thin-film display technology.

OLED is an organic material that, as the name implies, emits light when a current is passed through it. As opposed to LCD panels, which are back-lit, OLED displays are "always off" unless the individual pixels are electrified.

This means that OLED displays have much purer blacks and consume less energy when black or darker colours are displayed on-screen. However, lighter-coloured themes on AMOLED screens use considerably more power than an LCD using the same theme. OLED screens are also more expensive to produce than LCDs.

Because the black pixels are "off" in an OLED display, the contrast ratios are also higher compared to LCD screens. AMOLED displays have a very fast refresh rate too, but on the downside are not quite as visible in direct sunlight as backlit LCDs. Screen burn-in and diode degradation (because they are organic) are other factors to consider.Affiliate offer

OLED stands for Organic Light Emitting Diode. An OLED display is comprised of thin sheets of electroluminescent material, the main benefit of which is they produce their own light, and so don"t require a backlight, cutting down on energy requirements. OLED displays are more commonly referred to as AMOLED displays when used on smartphones or TVs.

As we"ve already covered, the AM part of AMOLED stands for Active Matrix, which is different from a Passive Matrix OLED (P-OLED), though these are less common in smartphones.

Super AMOLED is the name given by Samsung to its displays that used to only be found in high-end models but have now trickled down to more modestly specced devices. Like IPS LCDs, Super AMOLED improves upon the basic AMOLED premise by integrating the touch response layer into the display itself, rather than as an extra layer on top.

The latest evolution of the technology has been christened "Dynamic AMOLED". Samsung didn"t go into detail about what the term means, but highlighted that panels with such identification include HDR10+ certification that supports a wider range of contrast and colours, as well as blue light reduction for improved visual comfort.

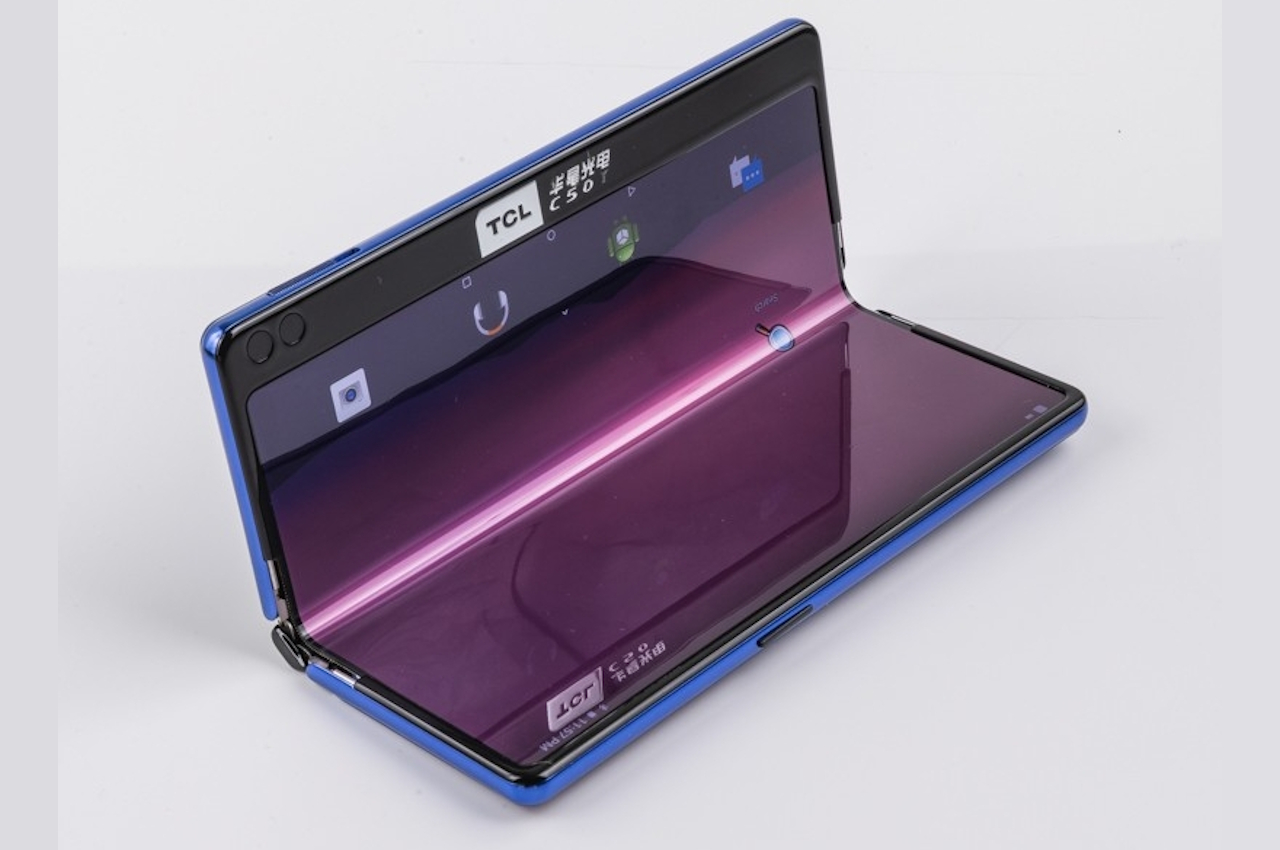

The technology debuted with the obscure Royole FlexPai, equipped with an OLED panel supplied by China"s BOE, and was then used in the Huawei Mate X (pictured above) and the Motorola Razr (2019), where both also sport BOE"s panel - and the Galaxy Flip and Fold lines, using the component supplied by Samsung Display.Affiliate offer

Resolution describes the number of individual pixels (or points) displayed on the screen and is usually presented for phones by the number of horizontal pixels — vertical when referring to TVs and monitors. More pixels on the same display allow for more detailed images and clearer text.

To make it easier to compare different models, brands usually adopt the same naming scheme made popular by the TV market with terms like HD, FullHD and UltraHD. But with phones adopting a wide range of different screen proportions, just knowing that is not enough to know the total pixels displayed on the screen.Common phone resolutions

But resolution in itself is not a good measure for image clarity, for that we need to consider the display size, resulting in the pixel density by area measured by DPI/PPI (dots/points per inch).Affiliate offer

Speaking of pixel density, this was one of Apple"s highlights back in 2010 during the launch of the iPhone 4. The company christened the LCD screen (LED, TFT, and IPS) used in the smartphone as "Retina Display", thanks to the high resolution of the panel used (960 by 640 pixels back then) in its 3.5-inch display.

The name coined by Apple"s marketing department is applied to screens which, according to the company, the human eye is unable to discern the individual pixels from a normal viewing distance. In the case of iPhones, the term was applied to displays with a pixel density that is greater than 300 ppi (dots per inch).

Since then, other manufacturers have followed suit, adopting panels with increasingly higher resolutions. While the iPhone 12 mini offers 476 dpi, models like Sony Xperia 1 boast a whopping 643 dpi.

With the iPhone 11 Pro, another term was introduced to the equation: "Super Retina XDR". Still using an OLED panel (that is supplied by Samsung Display or LG Display), the smartphone brings even higher specs in terms of contrast - with a 2,000,000:1 ratio and brightness level of 1,200 nits, which have been specially optimized for displaying content in HDR format.

As a kind of consolation prize for iPhone XR and iPhone 11 buyers, who continued relying on LCD panels, Apple classified the display used in the smartphones with a new term, "Liquid Retina". This was later applied also to the iPad Pro and iPad Air models, with the name defining screens that boast a high range and colour accuracy, at least based on the company"s standards.

Nit, or candela per square meter in the international system (cd/m²), is a unit of measurement of luminance, i.e. the intensity of light emitted. In the case of smartphone screens and monitors in general, such a value defines just how bright the display is - the higher the value, the more intense the light emitted by the screen.

The result is smoother animations on the phone, both during regular use and in games, compared to screens that have a 60 Hz refresh rate which remains the standard rate in the market when it comes to displays.

Originally touted to be a "gimmick" in 2017, with the launch of the Razer Phone, the feature gained more and more momentum in due time, even with a corresponding decrease in battery life. In order to make the most of this feature, manufacturers began to adopt screens with variable refresh rates, which can be adjusted according to the content displayed - which is 24 fps in most movies, 30 or 60 fps in home video recordings, and so forth.

The same unit of measurement is used for the sampling rate. Although similar, the value here represents the number of times per second the screen is able to register touches. The higher the sample rate, the faster the smartphone registers such touches, which results in a faster response time.

To further muddy the alphabet soup that we"ve come across, you will also run into other less common terms that are often highlighted in promotional materials for smartphones.

TFT(Thin Film Transistor) - a type of LCD display that adopts a thin semiconductor layer deposited on the panel, which allows for active control of the colour intensity in each pixel, featuring a similar concept as that of active-matrix (AM) used in AMOLED displays. It is used in TN, IPS/PLS, VA/PVA/MVA panels, etc.

IGZO(Indium Gallium Zinc Oxide) - a semiconductor material used in TFT films, which also allows higher resolutions and lower power consumption, and sees action in different types of LCD screens (TN, IPS, VA) and OLED displays

LTPO(Low Temperature Polycrystaline Oxide) - a technology developed by Apple that can be used in both OLED and LCD displays, as it combines LTPS and IGZO techniques. The result? Lower power consumption. It has been used in the Apple Watch 4 and the Galaxy S21 Ultra.

LTPO allows the display to adjust its refresh rate, adapting dynamically to the content shown. Scrolling pages can trigger the fastest mode for a fluid viewing, while displaying a static image allows the phone to use a lower refresh rate, saving the battery.

In 2022, flagship phones started using the so-called LTPO 2.0 tech, whose main advantage is being able to go down to a 1 Hz refresh rate, instead of the 10 Hz available in first-generation LTPO panels. Found in phones like the OnePlus 10 Pro and the Galaxy S22 Ultra, LTPO 2.0 promises even further energy savings.

Among televisions, the long-standing featured technology has always been miniLED - which consists of increasing the number of lighting zones in the backlight while still using an LCD panel. There are whispers going around that smartphones and smartwatches will be looking at incorporating microLED technology in their devices soon, with it being radically different from LCD/LED displays as it sports similar image characteristics to that of OLEDs.

By adopting a self-emitting light technology, microLED displays do not require the use of a backlight, with each pixel being "turned off" individually. The result is impressive: your eyes see the same level of contrast as OLED displays, without suffering from the risk of image retention or burn-in of organic diodes.

Each technology has its own advantages and disadvantages but in recent years, OLED screens have gained prominence, especially with the adoption of the component in high-end flagship smartphones. It gained an even greater degree of popularity after the launch of the iPhone X, which cemented the position of OLED panels in the premium segment.

As previously stated, OLED/AMOLED screens have the advantage of a varied contrast level, resulting from individual brightness control for the pixels. Another result of this is the more realistic reproduction of black, as well as low power consumption when the screen shows off dark images - which has also helped to popularize dark modes on smartphones.

While that is a very real possibility, it is not something that affects most users, who often confuse burn-in with a similar problem - image retention, which is temporary and usually resolves itself after a few minutes.

In the case of LCD displays, the main advantage lies in the low manufacturing cost, with dozens of players in the market offering competitive pricing and a high production volume. Some brands have taken advantage of this feature to prioritize certain features - such as a higher refresh rate - instead of adopting an OLED panel, such as the Xiaomi Mi 10T.

We start with the best design team in the point-of-purchase business, but we don’t stop there. Pratt Display also takes a proactive approach to technology adoption. Pratt is at the forefront of the retail display and packaging industry, leading in expertise and innovation. State-of-the-art software and machinery produce displays that set a high standard for precision, durability and functionality.

We demonstrate our commitment to sustainability by building displays from linerboard made with 100% recycled material. Our designers look to use less raw material through board-use efficiencies — allowing us to use less energy and fuel for manufacturing and transport, and to pass on cost savings to the customer.

Teaming with Pratt Display adds credibility to your commitment to green business practices. Based on the materials you choose and the run size of your project, we provide clients with scorecards, which put the sustainability of our processes and materials into easily visualized terms: trees saved, gallons of water saved by choosing recycled content.

Armed with high-quality raw materials and the latest software and machinery, our structural and graphic design teams provide expert service from concept to installation.

Our design team consults with the customer to run through the process and identify ways to streamline in three key areas: quality, time and cost. By starting with templates and then customizing for clients’ specific needs, we’re able to reduce costs, identify manufacturing efficiencies and save on labor involved in assembly.

What works in stores in Nebraska might not in stores on Long Island. That’s why Pratt takes a regional approach to the design and production of displays and packaging. Our regional studios know the local retail climate inside-and-out. With designers and account managers well versed in the local retail landscape, we bring the reach and resources of a national firm to the regional level. Proximity to both our clients and their retail partners allows for personalized service and cost savings on shipping and installation.

Pratt Display offers you the ability to visualize displays at all points in the process. Using the latest software, including Artios CAD, CAPE, TOPS, Illustrator, Photoshop, Strata 3D, SolidWorks, and Autodesk 3D MAX, our design team can create detailed renderings, specifications, die-lines, pallet patterns and other design-specific files and documentation.

You shouldn’t have to wait until displays and packaging end up in stores before you get a feel for how they’ll showcase your product. With detailed mockups created by large-format inkjet printers, you’ll know exactly what you’ll be getting before it’s too late to make adjustments.

Our clients won’t deal with surprise damage when displays arrive at mass retail locations. Ship testing means that all displays will be structurally sound. Pratt displays come through transport, distribution and delivery more than just intact, but as impressive and engaging as when they left the manufacturing facility.

Our lab conducts extensive testing to protect against nearly every threat our display may face on the way to the retail location. This includes strength and surface analysis, cyclic humidity studies, UN-DOT-Hazmat and ISTA shipping container certification, Amazon, UPS and FedEx testing, and paper and board/box testing. Test results are provided to customers in a comprehensive and detailed report, so you won’t have to deal with unforeseen issues when displays arrive at retail stores.

In a rapidly changing industry, our clients benefit from nimble and flexible manufacturing capabilities. Pratt Display delivers in key areas to help our clients keep up with growing demand and exacting brand standards.

Top-quality displays start with an investment in the latest technology, including 7-Color Martin DRO 1628 NT HBL rotary die cutters, high-speed multicolor presses and Automatan Litho Laminators, as well as the latest electrostatic Model EM labelers. Also enjoy precise finishing work that’s the result of the flexibility of flat-bed die cutting capacity provided by both large- and small-format specialty folder-gluers.

Demand for LTPS TFT LCD shipments rose 30 percent in September 2015 to reach 51.6 million units, due to strong demand from Apple and Chinese brands. Total smartphone panel shipments grew 4 percent month over month to reach 160 million units in September 2015. While amorphous silicon (a-Si) thin-film transistor (TFT) liquid-crystal display (LCD) panels continue to lead the smartphone display market, low-temperature polysilicon (LTPS) TFT LCD panel shipment share is growing, according to IHS Inc., a of critical information and insight.

“TFT-LCD, based on a-Si substrate, has been the leading panel technology for mobile phones because it is easy to manufacture and costs less to produce than other display technologies. However, since Apple adopted LTPS for its popular iPhones, demand for the new technology has continued to increase,” said Brian Huh, senior analyst for IHS Technology. “While LTPS panels cost greater, they boast lower power consumption and higher resolution compared to a-Si LCD panels. Greater demand for higher definition screens, especially in China, has also increased the adoption of LTPS LCD mobile phone displays.”

Based on the latest information in the IHS Smartphone Display Shipment Tracker,the market share for the a-Si TFT LCD panel fell 10 percent month over month, but the panel still comprised the majority of smartphone display shipments, reaching 79.6 million in September 2015. Active-matrix organic light-emitting diode (AMOLED) panel shipments grew 7 percent to reach just 25 million units.

As a point of differentiation in the smartphone display market, Samsung Electronics adopted AMOLED-based LTPS displays in 2009. At that time Samsung Display was not looking to expand its customer base because Samsung Electronics digested almost all of the company’s AMOLED capacity. However as Samsung Electronics’ AMOLED smartphone business began to decline last year, Samsung Display has been expanding its customer lineup. “Since the end of last year, Samsung Display has been actively and aggressively promoting AMOLED displays to other electronics companies, especially in China, and AMOLED panel shipments for Chinese brands have increased remarkably since September,” Huh said.

Total shipments of mobile phone displays, including thin-film transistor liquid crystal display (TFT LCD) and active matrix organic light-emitting diode (AMOLED) panels, reached 2.01 billion units in 2017, up 3 percent from 2016, according to preliminary estimate from business information provider IHS Markit (Nasdaq: INFO).

In the growing mobile phone display market, shipments of low-temperature-poly-silicon (LTPS) TFT LCD panels, which realize high-resolution images, increased by 21 percent to 620 million units in 2017 compared to the previous year. Shipments of amorphous silicon (a-Si) TFT LCD mobile phone panels declined 4 percent to 979 million units during the same period. Even though shipments of AMOLED panels jumped in the second half of 2017 thanks to the launch of the iPhone X, combined with the weak demand in the first half, its shipments were up just 3 percent to 402 million units in 2017.

In the smartphone-use LTPS TFT LCD market, Tianma, a leading small and medium panel supplier in China, has shown significant growth, expanding its shipments to Chinese smartphone set brands, such as Huawei and Xiaomi. In 2017, Tianma shipped 105 million LTPS TFT LCD panels for smartphones, almost double its shipments in 2016, with a market share of 17 percent, up 6 percentage points from 2016. It ranked the second largest LTPS TFT LCD supplier for smartphones in 2017, taking over LG Display with 16 percent, down 4 percentage points, and Sharp with 13 percent, down 1 percentage point. In 2017, Japan Display continued its market leader position but shed its share by 10 percentage points to 26 percent in 2017, according to the latest Smartphone Display Intelligent Service report by IHS Markit.

“LTPS TFT is a key technology to produce high-resolution displays for smartphones, and experience is required to optimize highly complex LTPS manufacturing process in each production fab. In terms of experience, Japanese and South Korean panel makers have a competitive advantage compared to Chinese makers,” said Hiroshi Hayase, senior director at IHS Markit. “However, Chinese LCD makers, such as Tianma and BOE, are catching up LTPS technology fast enough to support high demand from Chinese smartphone set makers.”

The Smartphone Display Intelligent Service by IHS Markit contains quarterly updates of smartphone display shipments and revenue by application, size, resolution and technology. It also provides supply chain information between display and set makers, as well as monthly smartphone display shipment and pricing information.

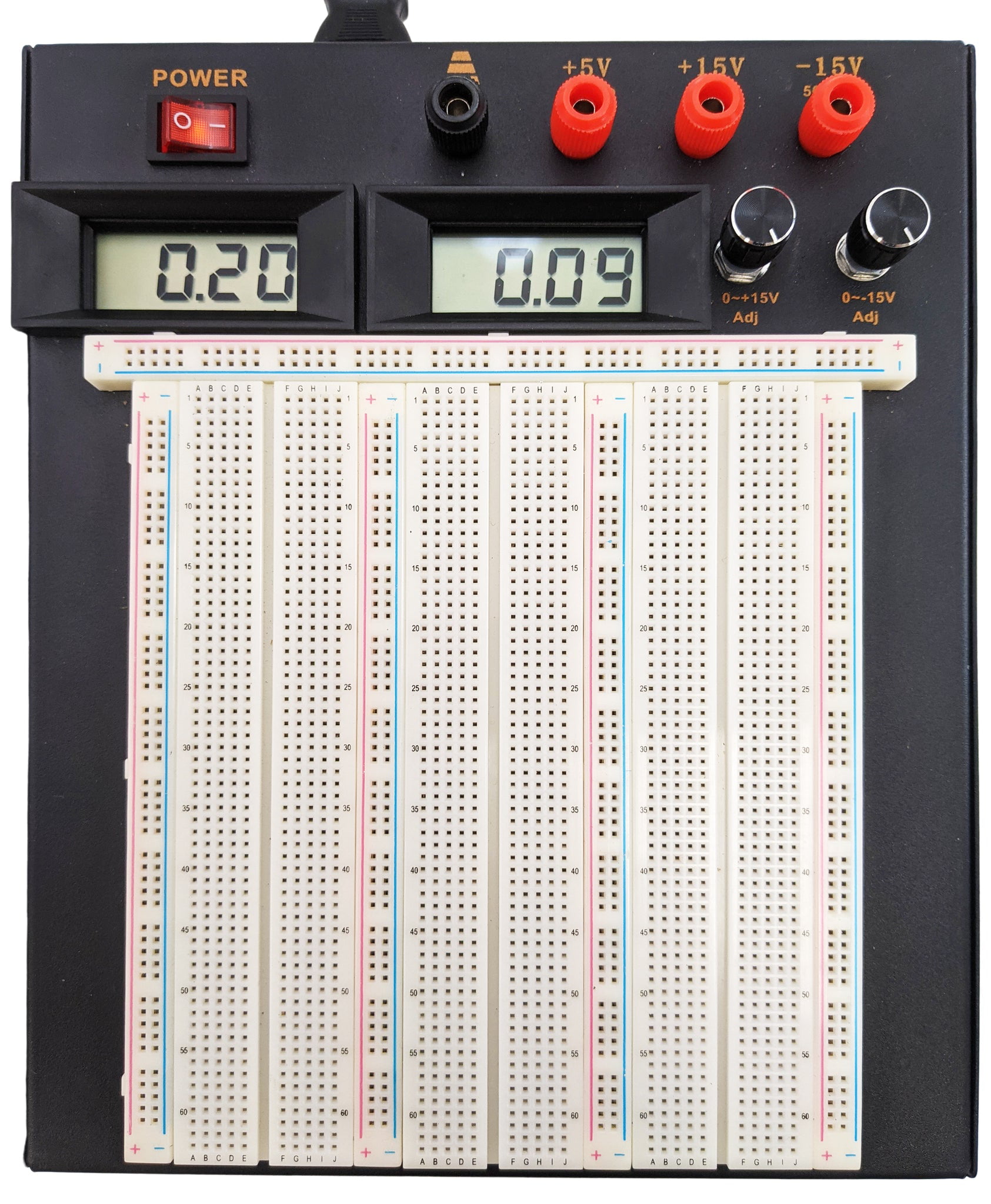

Monochrome character, graphic and static displays require different input voltages. All the different LCD voltage symbols can be confusing, but believe it or not, there is a system to the madness.

This LCD voltage terminology originated from the terminals of each type of transistor and their common connections in logic circuits. In other words, VCC is often applied to BJT (Bipolar Junction Transistor) collectors, VEE to BJT emitters, VDD to FET (Field-Effect Transistor) drains and VSS to FET sources. Most CMOS (Complementary metal–oxide–semiconductor) IC data sheets now use VCC and GND to designate the positive and negative supply pins.

In the Pleistocene era (1960’s or earlier), logic was implemented with bipolar transistors. NPN (Negative-Positive-Negative) were used because they were faster. It made sense to call positive supply voltage VCC where the “C” stands for collector. The negative supply was called VEE where “E” stands for emitter.

The convention of VAB means the voltage potential between VA and VB. The convention of using 3 letters was used to show power supply and ground reference voltages as well. In some cases a processor may have both an analog and digital power supply. In this case VCCA/VCCD and VSSA/VSSD are used. Another reason for the 3 letters is in an NPN circuit with a load resister between the collector and VCC. VC would be the collector voltage. In this case VCC is the positive power supply voltage and would be higher than VC.

Note: Most Segment, Character and Graphic displays will operate with a VDD of 5V or 3.3V. It may be possible to drive the display with as little as 3.0V, but the module may not perform very well in colder temperatures. The colder the ambient temperature, the more power is required to drive the segments.

Pin three (3) is Vo and is the difference in voltage between VDD and VSS. This LCD voltage is adjusted to provide the sharpest contrast. The adjustment can be accomplished through a fixed resistor or a variable potentiometer. Many products have firmware that monitor the temperature and automatically adjust the contrast voltage.

In a Liquid Crystal Display (LCD), V0 is used to vary the screen brightness or contrast. Contrast, simply put is the ratio of the light areas to the dark areas in a LCD. This is usually done in a production setting with values which are optimized for most users. Temperature can have an undesirable effect on the display brightness and for this reason a varying resister or potentiometer is used to accommodate the desires of the user.

Below is a data sheet of a 16x2 Character LCD module that shows various recommended driving voltages. The LCD voltage can range from MIN (minimum) to TYP (Typical) to Max (maximum).

If the supplied LCD voltage drops too low, the display is ‘under-driven’ and will produce segments that are ‘grey’. The lower the LCD voltage falls below the acceptable threshold, the lower the contrast will be.

If the LCD is over-driven, you may see ghosting. This is where segments that should not be ‘on’ are gray. They are not as dark as the segments that should be on, but they can be seen and may cause confusion for the end user.

There are times when a customer needs to replace a display that has been discontinued or EOL (End-Of -Life) by their previous LCD supplier. The previous LCD’s pin-outs may be different than Focus’ standard, off-the-shelf display. This is not a large problem to overcome.

The third option is to pull power from pins one and two. This is the same location from which the LCD is pulling its power. Focus does not recommend this option and can modify the PCB for the customer to connect the backlight from a different location.

Many LCD Modules will require more than one internal voltage/current. This may make it necessary for the customer to supply the needed inputs. They may need to supply 3V, 5V, 9V, -12V etc.

The solution for this is to integrate a charge pump (or booster circuit) into the LCD circuitry. This solution works in most applications, but if the product will be operating in an intrinsic environment, care must be taken with layout of the circuit board.

Intrinsically-safe LCDs are Liquid Crystal Displays that are designed to operate in conditions where an arc or spark can cause an explosion. In these cases, charge pumps cannot be employed. In fact, the total capacitive value of the display needs to be kept to a minimum.

Focus Display Solutions does not build a display that is labeled ‘Intrinsically safe’ but we do design the LCD to meet the requirements of the engineer. In meeting the design engineer’s requirements, the display may need to contain two or three independent inputs. Focus can redesign the PCB and lay out the traces to allow for these additional inputs.

If you spend long enough debating the merits of LCD vs. OLED display technologies, eventually, someone will touch upon the subject of the dreaded OLED screen burn in. The point made is that OLED displays will inevitably suffer from horrible-looking artifacts over time, while LCD and new technologies like Mini-LED won’t. But like most of these debates, you’ll probably hear as many overblown anecdotes as you will actual facts about the issue.

You may never have experienced it for yourself, but many consumers are wary about the possibility of burn in when pondering their next smartphone purchase. Particularly as expensive flagship smartphones have universally adopted OLED display technology. Apple, Google, and other manufacturers acknowledge that burn in can be a problem in rare cases. OLED technology has made its way to much more affordable price points in recent years, putting the issue on the radar for even more consumers.

The word “burn in” is a little misleading, as no actual burning or heat problems are involved. Instead, this term describes a display suffering from permanent discoloration across any part of the panel. This may take the form of a text or image outline, fading of colors, or other noticeable patches and patterns on display. The display still works as expected, but a somewhat noticeable ghost image or discoloration persists when the screen is on. To be considered screen burn in, these artifacts have to be permanent and are a defect caused on the display hardware side. Rather than a graphical glitch that may be caused by software, temporary image retention, or a problem with the display driver circuitry.

The term dates back to old CRT monitors, where phosphor compounds that emit light to produce images lost their luminance with time. LCD panels can exhibit similar problems, but these are much rarer due to the nature of LCD’s backlight and color matrix design.

Although not as bad or noticeable as old CRT issues, today’s OLED smartphone displays can eventually suffer from a similar problem. That being said, it’s pretty difficult and rare to notice unless you know what you’re looking for, and it takes hundreds, if not thousands, of hours of screen-on time before any such errors appear. In smartphones, pattern burn in is typically associated with always-on displays, navigation buttons, and the notification bar. The example below demonstrates a textbook case:

Although most smartphones now support gesture navigation controls in the place of the old button design. So this type of burn-in is much less of a problem than it used to be.

The cause of all screen burn in is the varying lifecycle of a display’s light-producing components. As these parts age, their brightness changes, and therefore the panel’s color reproduction gradually shifts with time. Although this can be mitigated somewhat with clever software, all displays experience some color shift as they age. But with burn in, some parts of the screen age faster than others. This can gradually shift the perceivable colors of the screen in one area more than in another, leaving what looks like a ghost image behind.

With modern smartphone and smartwatch technology, screen burn in can manifest due to the different life spans between the red, green, and blue LED subpixels used in OLED panels. As we mentioned before, areas of the display that seldom change, are bright white, or are often black and switched off, such as navigation buttons or the notification bar, are the most likely areas to notice this issue. You may also notice the effect in darkened status bars designed to hide display notches.

So, if one part of the panel spends a lot of time displaying a blue or white image, the blue pixels in this area will degrade faster than in other areas. That’s essentially what burn in is. However, display manufacturers do account for this in their panel designs.

If OLED screens have a problem with burn in, why do we continue using them? Burn in is a true downside to OLED displays, but there are plenty of reasons consumers and manufacturers like them. For starters, image quality is much better than in LCDs. OLED panels can reproduce more vibrant colors, more contrast, wider viewing angles, and faster refresh rates. Colors tend to be much more saturated, and blacks are much darker.

OLED displays have a simpler design, allowing thinner, lighter smartphone designs. You can also thank OLED technology for foldable phones and curved displays. If those improvements weren’t enough, you’ll also enjoy lower power consumption with OLED.

Additionally, burn in problems are only common after prolonged periods of use. As you may already know, smartphone manufacturers don’t expect you to keep a smartphone for more than 2-3 years. Recent statistics show that consumers currently keep their phones for an average of 2.75 years.

At this stage, manufacturers are very aware of the potential issues and have already taken some intelligent steps to help avoid burn in. For starters, Samsung has been using its pentile subpixel arrangement in its AMOLED displays since the Galaxy S3. By making the blue subpixel larger, it requires less current to drive in order to provide the necessary light. Driving the LED with less current increases its lifespan, so it takes longer for any noticeable color shift to occur.

This doesn’t directly address the issue of different parts of the screen aging at different rates, but it does mean that it will take significantly longer to notice than with older or cheaper OLED panels. More expensive and modern OLED panels are built with longer-lasting LEDs and well-designed layouts, meaning flagship smartphone displays age slower. These days, it’s cheaper phones packing cheaper displays that are marginally more likely to see issues after heavy use.

There are software solutions too. Android Wear product manufacturers can enable the OS’s “burn protection” option. This mode periodically shifts the screen’s contents by a few pixels, so they spend equal time displaying different colors. Smartphones equipped with Always-On display technology employ a similar tactic. Google also suggests a selection of design guidelines tailored to avoid screen burn-in problems when designing OLED watches. The move towards gesture rather than on-screen navigation controls is also helping to alleviate one of the more noticeable burn in areas.

Try to make it so that the screen isn’t displaying the same thing all the time, in the same areas of the screen. For example, if you have a widget that almost always looks the same, chances are it will eventually burn into the image. Move things around now and then, and try to keep the view of your phone dynamic.

All that said, screen burn in isn’t something that should concern many users if they’re looking to buy a new OLED smartphone. Modern panels have much longer lifespans than early OLED smartphones, and even then, burn in was rare. Just don’t leave a static image on the screen 24/7 with the brightness set at max.

The bottom line is that you should be looking at several years’ worth of use out of a modern smartphone display before any screen burn in will be noticeable. But it doesn’t hurt to be aware of what can happen to aging handsets and how to maximize their lifespan.

Display technologies are advancing every day. All the major tech giants like Apple, Samsung, One Plus use one among these technologies for building the displays of their Apple phones or Galaxy Notes. Each has its advantages and disadvantages. So which one is better? Is it the AMOLED favored mostly by Samsung? Or is it the IPS LCD favored by Apple for their iPhones? Let us take a detailed look at the features of AMOLED vs IPS display technologies.

AMOLED stands for Active-Matrix Organic Light-Emitting Diode is a type of display used mainly in mobile phones. You might have seen the AMOLED display mentioned in the specifications for smart devices, especially mobile phones. They are also used in smartwatches, laptops, and even televisions. Let’s see what the terms in AMOLED mean.

You might be familiar with the giant LED bulbs used at parties or even as indicators on televisions showing the on/off state. These same LED lights are used in AMOLEDs, but of course in the smallest size possible. The LEDs used are in the primary shades namely Red, Blue, and Green, and are grouped in triangle-shaped pixelated forms.

The Organic Light Emitting Diode is commonly referred to as OLED. It is pronounced as “oh-led”. OLED is a type of display in which each LED lights up one at a time. When you light them up together in different intensities, you will get more colors in the spectrum. So all LEDs switched on at the same time give you white color and similarly switching off all the LEDs together gives black color. An OLED display is comprised of a substrate, an anode, a conductive layer, an emissive layer, a cathode, and the cover. The substrate is either plastic or glass that supports the display panel.

Compared to the LCD and LED displays, the diodes in the OLED display produce light individually meaning they do not need a backlight like their predecessors. OLEDs use lesser electricity and are thinner compared to LEDs. They are also bendable and may even be curved. However, they are much more expensive than LED displays. Hence in the earlier days, it was majorly used for displays for

Now the technologies mentioned above combine to give the AMOLED displays. Here an OLED display is driven with an active matrix control scheme. The TFTs (thin-film transistors) turn on/off each pixel one at a time. The other scheme where the OLEDs are controlled by a passive matrix requires each grid ( rows and lines) to be controlled together. The advanced AMOLED displays allow for higher resolution display with a much bigger physical size.

AMOLEDs have deep black lights. The blacks are darker than LEDs and LCDs because parts of the screen can be switched off altogether. AMOLEDs are also thinner and lighter than LCDs. This feature especially stands out in a dark theater room where OLED displays give a higher contrast ratio compared to LCDs making for an excellent visual experience. This feature of OLED which can work with no backlight makes it better than LCDs whether or not they have an LED backlight.

Since they use Active Matrix technology over the passive matrix version, AMOLEDs have a faster response time. They are up to a millisecond faster and extract less power from your mobile phone’s battery. Extended battery life means major advantages in the portability department. This adding to its high display features leads to them being extensively used. They are preferred over the other versions by major companies like Samsung. Speaking of power, the amount consumed by an OLED display varies according to the brightness and color of the picture displayed.

One of the disadvantages the AMOLED had over LCD was the blurriness caused in sunlight which is a result of its lowered peak-brightness values. This issue was corrected in the advanced Super AMOLEDs. In the Super AMOLEDs, the size of gaps between the various layers of the screen namely the cathode layer, anode layer, organic active layer, TFT layer is made narrower than before.

Another problem associated with the AMOLEDs is that the organic materials used in the emissive layer and the conductive layer suffer degradation. This happens comparatively in a short amount of time. As a result, various display problems arise including image persistence, burn-in, etc which are essentially screen burn type problems and color shifts where some colors fade quicker than others. Burn-in is essentially the pixel quality becoming trash after a while because of the degradation of the organic molecules.

Most flagship models of major companies like Samsung, Apple, and One Plus use either super AMOLED or IPS panel premium LCDs. So what exactly is an IPS display? and how does it feature against like the likes of super AMOLEDs?

First, let us understand the basics of a standard LCD. Simply put, when you apply current to some crystals, they may or may not let through the light which comes from a backlight that covers the whole display. In addition to this, there are polarization and color filters present in LCDs which finally give the primary colors Red, Blue, and Green.

Before we get into detailed explanations, you have to keep in mind that for the final end-product that ends up on the market, the quality of the display does not solely depend on whether it is IPS or AMOLED. The companies usually put their tweaks on top of the existing technology before making them available in the market. AMOLEDs are a newer technology than IPS LCD and improve on it in some areas while still lagging in others.

The IPS LCD stands for In-Plane Switching Liquid Crystal Displays. It emerged onto the scene as an improvement on the existing and vulnerable Thin Film Transistor LCD technology commonly referred to as the TFT. Samsung was the leading manufacturer to employ Super AMOLEDs. The IPS display is mainly being used in Apple iPhones. Apple beginning with the iPhone X is switching to AMOLED displays with contrast ratios of 1000000 to 1

As said before, an IPS display is an improved version of the regular TFT LCDs. Here, the difference comes in the way the anode and the cathode are arranged. They are planted as strip electrodes on one of the two glass substrates.

The IPS display scores big time when it comes to offering better viewing angles compared to the other LCD technologies like Twisted Nematic LCD (TN) and Vertical Alignment LCD (VA). The IPS display can be viewed without any color degradation or blurriness at flimsy shallow angles compared to TN and VA displays.

The consistency of colors and clarity of pictures at wider viewing angles is the major advantage of an LCD. IPS displays have higher resolution. They also can display a wide range of colors. These features also make the IPS displays costlier than TN and VA LCDs. Normally IPS monitors allow up to 178 degrees of viewing angles. These displays almost guarantee absolute color accuracy.

For other LCD models, the color and the brightness of an image vary when viewed from different angles. Compared with them, IPS displays are more suited for someone working as a visual/graphic artist. As a regular television, all LCD models are mostly considered equally good. This is because the viewers would mostly be sitting right in front of the screen where these differences between the models do not matter.

IPS displays are capable of displaying a wider spectrum of colors. Considering no monitors can display the entire color spectrum visible to the human eye, IPS LCD panels are the closest things to a perfect display monitor far better than TN and VA LCDs

Image retention is a problem often associated with LCDs. This happens because of the crystal which gets into a particular position for the light to go through stays in that same spot without falling back into its original position. This leads to some parts of the image being left on the screen. This is, however, a temporary problem. The crystal will eventually twist back into the position when the current is applied to it again. When it comes to color accuracy, the previous generation of LCDs was no match for the AMOLED. They had the highest color accuracy among mobile phones. But recent versions of the LCDs have fared much better versus their counterparts.

Large-sized IPS monitors are not affordable for the average customer. They should be avoided since they offer nothing impressive over other LCDs considering the price range. However, if you are a visual artist or a photographer, IPS displays provide the best color accuracy in the market. It would be more beneficial to you compared to an ordinary TN display unit.

AMOLEDs and IPS LCDs are two sides of the same coin in a sense. They both got their advantages and disadvantages. Their disadvantages are mostly overshadowed by the many tweaks installed by the parent companies to ensure customer satisfaction. From high power consumption to ugly blacks, the flaws are minimized in every newer version.

Touch panel technologies are a key theme in current digital devices, including smartphones, slate devices like the iPad, the screens on the backs of digital cameras, the Nintendo DS, and Windows 7 devices. The term touch panel encompasses various technologies for sensing the touch of a finger or stylus. In this session, we"ll look at basic touch panel sensing methods and introduce the characteristics and optimal applications of each.

Note: Below is the translation from the Japanese of the ITmedia article "How Can a Screen Sense Touch? A Basic Understanding of Touch Panels"published September 27, 2010. Copyright 2011 ITmedia Inc. All Rights Reserved.

A touch panel is a piece of equipment that lets users interact with a computer by touching the screen directly. Incorporating features into the monitor like sensors that detect touch actions makes it possible to issue instructions to a computer by having it sense the position of a finger or stylus. Essentially, it becomes a device fusing the two functions of display and input.

It"s perhaps not something we think of often, but touch panels have integrated themselves into every aspect of our lives. People who enjoy using digital devices like smartphones interact with touch panels all the time in everyday life—but so do others, at devices like bank ATMs, ticket vending machines in railway stations, electronic kiosks inside convenience stores, digital photo printers at mass merchandisers, library information terminals, photocopiers, and car navigation systems.

A major factor driving the spread of touch panels is the benefits they offer in the way of intuitive operation. Since they can be used for input through direct contact with icons and buttons, they"re easy to understand and easily used, even by people unaccustomed to using computers. Touch panels also contribute to miniaturization and simplification of devices by combining display and input into a single piece of equipment. Since touch panel buttons are software, not hardware, their interfaces are easily changed through software.

While a touch panel requires a wide range of characteristics, including display visibility above all, along with precision in position sensing, rapid response to input, durability, and installation costs, their characteristics differ greatly depending on the methods used to sense touch input. Some typical touch-panel sensing methods are discussed below.

As of 2010, resistive film represented the most widely used sensing method in the touch panel market. Touch panels based on this method are called pressure-sensitive or analog-resistive film touch panels. In addition to standalone LCD monitors, this technology is used in a wide range of small to mid-sized devices, including smartphones, mobile phones, PDAs, car navigation systems, and the Nintendo DS.

With this method, the position on screen contacted by a finger, stylus, or other object is detected using changes in pressure. The monitor features a simple internal structure: a glass screen and a film screen separated by a narrow gap, each with a transparent electrode film (electrode layer) attached. Pressing the surface of the screen presses the electrodes in the film and the glass to come into contact, resulting in the flow of electrical current. The point of contact is identified by detecting this change in voltage.

The advantages of this system include the low-cost manufacture, thanks to its simple structure. The system also uses less electricity than other methods, and the resulting configurations are strongly resistant to dust and water since the surface is covered in film. Since input involves pressure applied to the film, it can be used for input not just with bare fingers, but even when wearing gloves or using a stylus. These screens can also be used to input handwritten text.

Drawbacks include lower light transmittance (reduced display quality) due to the film and two electrode layers; relatively lower durability and shock resistance; and reduced precision of detection with larger screen sizes. (Precision can be maintained in other ways—for example, splitting the screen into multiple areas for detection.)

Capacitive touch panels represent the second most widely used sensing method after resistive film touch panels. Corresponding to the terms used for the above analog resistive touch panels, these also are called analog capacitive touch panels. Aside from standalone LCD monitors, these are often used in the same devices with resistive film touch panels, such as smartphones and mobile phones.

With this method, the point at which the touch occurs is identified using sensors to sense minor changes in electrical current generated by contact with a finger or changes in electrostatic capacity (load). Since the sensors react to the static electrical capacity of the human body when a finger approaches the screen, they also can be operated in a manner similar to moving a pointer within an area touched on screen.

Two types of touch panels use this method: surface capacitive touch panels and projective capacitive touch panels. The internal structures differ between the two types.

Surface capacitive touch panels are often used in relatively large panels. Inside these panels, a transparent electrode film (electrode layer) is placed atop a glass substrate, covered by a protective cover. Electric voltage is applied to electrodes positioned in the four corners of the glass substrate, generating a uniform low-voltage electrical field across the entire panel. The coordinates of the position at which the finger touches the screen are identified by measuring the resulting changes in electrostatic capacity at the four corners of the panel.

While this type of capacitive touch panel has a simpler structure than a projected capacitive touch panel and for this reason offers lower cost, it is structurally difficult to detect contact at two or more points at the same time (multi-touch).

Projected capacitive touch panels are often used for smaller screen sizes than surface capacitive touch panels. They"ve attracted significant attention in mobile devices. The iPhone, iPod Touch, and iPad use this method to achieve high-precision multi-touch functionality and high response speed.

The internal structure of these touch panels consists of a substrate incorporating an IC chip for processing computations, over which is a layer of numerous transparent electrodes is positioned in specific patterns. The surface is covered with an insulating glass or plastic cover. When a finger approaches the surface, electrostatic capacity among multiple electrodes changes simultaneously, and the position were contact occurs can be identified precisely by measuring the ratios between these electrical currents.

A unique characteristic of a projected capacitive touch panel is the fact that the large number of electrodes enables accurate detection of contact at multiple points (multi-touch). However, the projected capacitive touch panels featuring indium-tin-oxide (ITO) found in smartphones and similar devices are poorly suited for use in large screens, since increased screen size results in increased resistance (i.e., slower transmission of electrical current), increasing the amount of error and noise in detecting the points touched.

Larger touch panels use center-wire projected capacitive touch panels in which very thin electrical wires are laid out in a grid as a transparent electrode layer. While lower resistance makes center-wire projected capacitive touch panels highly sensitive, they are less suited to mass production than ITO etching.

Above, we"ve summarized the differences between the two types of capacitive touch panels. The overall characteristics of such panels include the fact that unlike resistive film touch panels, they do not respond to touch by clothing or standard styli. They feature strong resistance to dust and water drops and high durability and scratch resistance. In addition, their light transmittance is higher, as compared to resistive film touch panels.

On the other hand, these touch panels require either a finger or a special stylus. They cannot be operated while wearing gloves, and they are susceptible to the effects of nearby metal structures.

Surface acoustic wave (SAW) touch panels were developed mainly to address the drawbacks of low light transmittance in resistive film touch panels—that is, to achieve bright touch panels with high levels of visibility. These are also called surface wave or acoustic wave touch panels. Aside from standalone LCD monitors, these are widely used in public spaces, in devices like point-of-sale terminals, ATMs, and electronic kiosks.

These panels detect the screen position where contact occurs with a finger or other object using the attenuation in ultrasound elastic waves on the surface. The internal structure of these panels is designed so that multiple piezoelectric transducers arranged in the corners of a glass substrate transmit ultrasound surface elastic waves as vibrations in the panel surface, which are received by transducers installed opposite the transmitting ones. When the screen is touched, ultrasound waves are absorbed and attenuated by the finger or other object. The location is identified by detecting these changes. Naturally, the user does not feel these vibrations when touching the screen. These panels offer high ease of use.

The strengths of this type of touch panel include high light transmittance and superior visibility, since the structure requires no film or transparent electrodes on the screen. Additionally, the surface glass provides better durability and scratch resistance than a capacitive touch panel. Another advantage is that even if the surface does somehow become scratched, the panel remains sensitive to touch. (On a capacitive touch panel, surface scratches can sometimes interrupt signals.) Structurally, this type of panel ensures high stability and long service life, free of changes over time or deviations in position.

Weak points include compatibility with only fingers and soft objects (such as gloves) that absorb ultrasound surface elastic waves. These panels require special-purpose styluses and may react to substances like water drops or small insects on the panel.

All in all, however, these touch panels offer relatively few drawbacks. Recent developments such as improvements in manufacturing technology are also improving their cost-performance.

The category of optical touch panels includes multiple sensing methods. The number of products employing infrared optical imaging touch panels based on infrared image sensors to sense position through triangulation has grown in recent years, chiefly among larger panels.

A touch panel in this category features one infrared LED each at the left and right ends of the top of the panel, along with an image sensor (camera). Retroreflective tape that reflects incident light along the axis of incidence is affixed along the remaining left, right, and bottom sides. When a finger or other object touches the screen, the image sensor captures the shadows formed when the infra

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey