1602 lcd module tutorial for sale

LCD Display Modules└ LEDs, LCDs & Display Modules└ Electronic Components & Semiconductors└ Electrical Equipment & Supplies└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Do you want your Arduino projects to display status messages or sensor readings? Then these LCD displays can be a perfect fit. They are extremely common and fast way to add a readable interface to your project.

This tutorial will help you get up and running with not only 16×2 Character LCD, but any Character LCD (16×4, 16×1, 20×4 etc.) that is based on Hitachi’s LCD Controller Chip – HD44780.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

The good news is that all of these displays are ‘swappable’, which means if you build your project with one you can just unplug it and use another size/color LCD of your choice. Your code will have to change a bit but at least the wiring remains the same!

Vo (LCD Contrast) controls the contrast and brightness of the LCD. Using a simple voltage divider with a potentiometer, we can make fine adjustments to the contrast.

RS (Register Select) pin is set to LOW when sending commands to the LCD (such as setting the cursor to a specific location, clearing the display, etc.) and HIGH when sending data to the LCD. Basically this pin is used to separate the command from the data.

R/W (Read/Write) pin allows you to read data from the LCD or write data to the LCD. Since we are only using this LCD as an output device, we are going to set this pin LOW. This forces it into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD does not care what is happening on the R/W, RS, and data bus lines. When this pin is set to HIGH, the LCD processes the incoming data.

Now we will power the LCD. The LCD has two separate power connections; One for the LCD (pin 1 and pin 2) and the other for the LCD backlight (pin 15 and pin 16). Connect pins 1 and 16 of the LCD to GND and 2 and 15 to 5V.

Most LCDs have a built-in series resistor for the LED backlight. You’ll find this near pin 15 on the back of the LCD. If your LCD does not include such a resistor or you are not sure if your LCD has one, you will need to add one between 5V and pin 15. It is safe to use a 220 ohm resistor, although a value this high may make the backlight a bit dim. For better results you can check the datasheet for maximum backlight current and select a suitable resistor value.

Next we will make the connection for pin 3 on the LCD which controls the contrast and brightness of the display. To adjust the contrast we will connect a 10K potentiometer between 5V and GND and connect the potentiometer’s center pin (wiper) to pin 3 on the LCD.

That’s it. Now turn on the Arduino. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

Let’s finish connecting the LCD to the Arduino. We have already made the connections to power the LCD, now all we have to do is make the necessary connections for communication.

We know that there are 8 data pins that carry data to the display. However, HD44780 based LCDs are designed in such a way that we can communicate with the LCD using only 4 data pins (4-bit mode) instead of 8 (8-bit mode). This saves us 4 pins!

The sketch begins by including the LiquidCrystal library. The Arduino community has a library called LiquidCrystal which makes programming of LCD modules less difficult. You can find more information about the library on Arduino’s official website.

First we create a LiquidCrystal object. This object uses 6 parameters and specifies which Arduino pins are connected to the LCD’s RS, EN, and four data pins.

In the ‘setup’ we call two functions. The first function is begin(). It is used to specify the dimensions (number of columns and rows) of the display. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

After that we set the cursor position to the second row by calling the function setCursor(). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

As discussed earlier in this tutorial a character is made up of a 5×8 pixel matrix, so you need to define your custom character within that matrix. You can use the createChar() function to define a character.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

In this Step I cover four (4) animation examples: an animated Emoji, an animated arrow, an animated bouncing ball, going from left to right, and an animated bouncing ball in the same location on the LCD.

Of course, if the delay is reduced from its current setting of 1,500ms, as is appropriate for a tutorial - so changes can be seen, to a lesser value, the animation would move more quickly.

Below we design two (2) custom characters: a custom arrow and a blank character. That is, the first custom character designed is an arrow. The second is a blank character that will be used to remove each arrow after it is displayed. The custom arrow character is displayed in each of the sixteen (16) visible character positions on the second row, and then removed from each position it appears in. Here we use a 250 ms pause between consecutive arrow displays, to allow each arrow to be easily seen, as is appropriate for a tutorial.

Alternating ball characters are displayed in turn at every other one of the sixteen (16) visible character positions (i.e, first ball1 is displayed and then in the next position ball2) on the second row. These are then, subsequently, removed from each position the balls appear in. Here again, we delay 250 ms between displays, so each ball can be easily seen - as is appropriate for a tutorial. Any delay equal to or greater than 200 ms will also work.

Lastly, If we change the ball characters slightly, so they are even more visible, and write them to the same location, and shorten the delay. We bounce the ball, i.e., animate it, in the same LCD location.

In this Arduino LCD I2C tutorial, we will learn how to connect an LCD I2C (Liquid Crystal Display) to the Arduino board. LCDs are very popular and widely used in electronics projects for displaying information. There are many types of LCD. This tutorial takes LCD 16x2 (16 columns and 2 rows) as an example. The other LCDs are similar.

In the previous tutorial, we had learned how to use the normal LCD. However, wiring between Arduino and the normal LCD is complicated. Therefore, LCD I2C has been created to simplify the wiring. Actually, LCD I2C is composed of a normal LCD, an I2C module and a potentiometer.

We are considering to make the video tutorials. If you think the video tutorials are essential, please subscribe to our YouTube channel to give us motivation for making the videos.

lcd.print() function supports only ASCII characters. If you want to display a special character or symbol (e.g. heart, angry bird), you need to use the below character generator.

Depending on manufacturers, the I2C address of LCD may be different. Usually, the default I2C address of LCD is 0x27 or 0x3F. Try these values one by one. If you still failed, run the below code to find the I2C address.

※ OUR MESSAGESYou can share the link of this tutorial anywhere. Howerver, please do not copy the content to share on other websites. We took a lot of time and effort to create the content of this tutorial, please respect our work!

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

We hope you’ve found this tutorial useful. If you like ESP32 and you want to learn more, we recommend enrolling in Learn ESP32 with Arduino IDE course.

This tutorial includes everything you need to know about controlling a character LCD with Arduino. I have included a wiring diagram and many example codes. These displays are great for displaying sensor data or text and they are also fairly cheap.

As you will see, you need quite a lot of connections to control these displays. I therefore like to use them with an I2C interface module mounted on the back. With this I2C module, you only need two connections to control the LCD. Check out the tutorial below if you want to use an I2C module as well:

These LCDs are available in many different sizes (16×2 1602, 20×4 2004, 16×1 etc.), but they all use the same HD44780 parallel interface LCD controller chip from Hitachi. This means you can easily swap them. You will only need to change the size specifications in your Arduino code.

For more information, you can check out the datasheets below. The 16×2 and 20×4 datasheets include the dimensions of the LCD and in the HD44780 datasheet you can find more information about the Hitachi LCD driver.

Most LCDs have a built-in series resistor for the LED backlight. You should find it on the back of the LCD connected to pin 15 (Anode). If your display doesn’t include a resistor, you will need to add one between 5 V and pin 15. It should be safe to use a 220Ω resistor, but this value might make your display a bit dim. You can check the datasheet for the maximum current rating of the backlight and use this to select an appropriate resistor value.

After you have wired up the LCD, you will need to adjust the contrast of the display. This is done by turning the 10 kΩ potentiometer clockwise or counterclockwise.

Plug in the USB connector of the Arduino to power the LCD. You should see the backlight light up. Now rotate the potentiometer until one (16×2 LCD) or 2 rows (20×4 LCD) of rectangles appear.

In order to control the LCD and display characters, you will need to add a few extra connections. Check the wiring diagram below and the pinout table from the introduction of this article.

We will be using the LCD in 4-bit mode, this means you don’t need to connect anything to D0-D3. The R/W pin is connected to ground, this will pull the pin LOW and set the LCD to WRITE mode.

To control the LCD we will be using the LiquidCrystal library. This library should come pre-installed with the Arduino IDE. You can find it by going to Sketch > Include Library > LiquidCrystal.

The example code below shows you how to display a message on the LCD. Next, I will show you how the code works and how you can use the other functions of the LiquidCrystal library.

After including the library, the next step is to create a new instance of the LiquidCrystal class. The is done with the function LiquidCrystal(rs, enable, d4, d5, d6, d7). As parameters we use the Arduino pins to which we connected the display. Note that we have called the display ‘lcd’. You can give it a different name if you want like ‘menu_display’. You will need to change ‘lcd’ to the new name in the rest of the sketch.

In the loop() the cursor is set to the third column and first row of the LCD with lcd.setCursor(2,0). Note that counting starts at 0, and the first argument specifies the column. If you do not specify the cursor position, the text will be printed at the default home position (0,0) if the display is empty, or behind the last printed character.

Next, the string ‘Hello World!’ is printed with lcd.print("Hello World!"). Note that you need to place quotation marks (” “) around the text. When you want to print numbers or variables, no quotation marks are necessary.

Clears the LCD screen and positions the cursor in the upper-left corner (first row and first column) of the display. You can use this function to display different words in a loop.

This function turns off any text or cursors printed to the LCD. The text/data is not cleared from the LCD memory. This means it will be shown again when the function display() is called.

This function turns on automatic scrolling of the LCD. This causes each character output to the display to push previous characters over by one space. If the current text direction is left-to-right (the default), the display scrolls to the left; if the current direction is right-to-left, the display scrolls to the right. This has the effect of outputting each new character to the same location on the LCD.

The following example sketch enables automatic scrolling and prints the character 0 to 9 at the position (16,0) of the LCD. Change this to (20,0) for a 20×4 LCD.

With the function createChar() it is possible to create and display custom characters on the LCD. This is especially useful if you want to display a character that is not part of the standard ASCII character set.

Technical info: LCDs that are based on the Hitachi HD44780 LCD controller have two types of memories: CGROM and CGRAM (Character Generator ROM and RAM). CGROM generates all the 5 x 8 dot character patterns from the standard 8-bit character codes. CGRAM can generate user-defined character patterns.

/* Example sketch to create and display custom characters on character LCD with Arduino and LiquidCrystal library. For more info see www.www.makerguides.com */

After including the library and creating the LCD object, the custom character arrays are defined. Each array consists of 8 bytes, 1 byte for each row. In this example 8 custom characters are created.

In this article I have shown you how to use an alphanumeric LCD with Arduino. I hope you found it useful and informative. If you did, please share it with a friend that also likes electronics and making things!

I would love to know what projects you plan on building (or have already built) with these LCDs. If you have any questions, suggestions, or if you think that things are missing in this tutorial, please leave a comment down below.

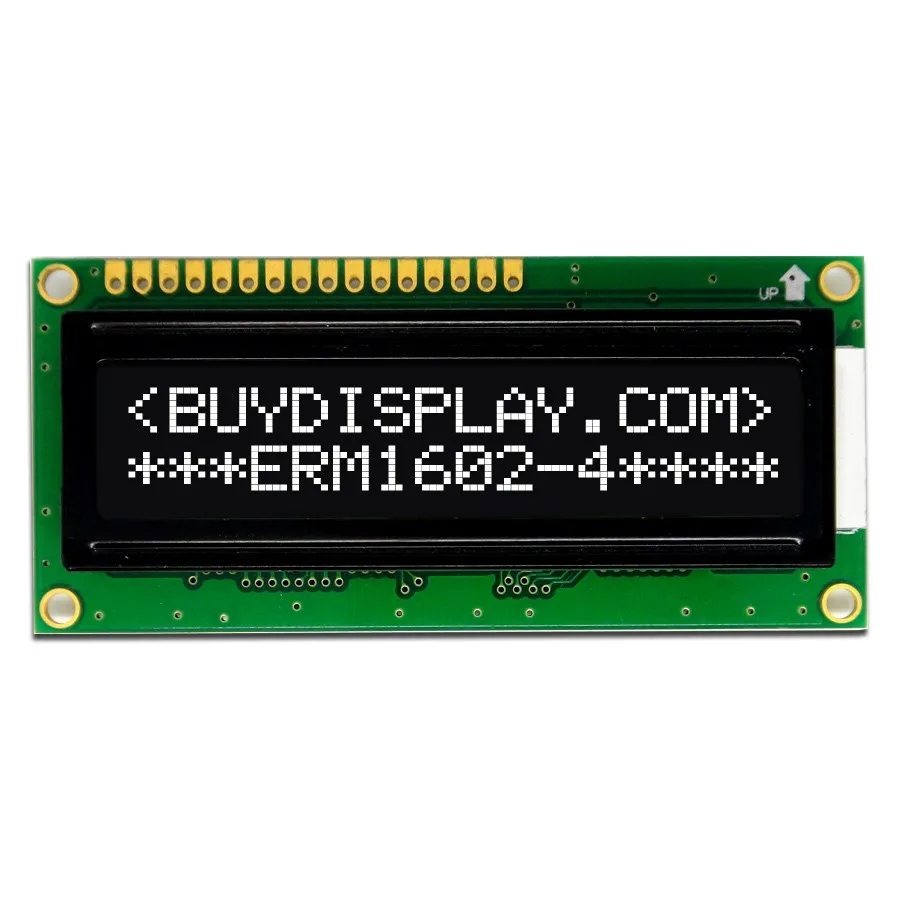

ERM1602SYG-6 is 16 characters wide,2 rows character lcd module,SPLC780C controller (Industry-standard HD44780 compatible controller),6800 4/8-bit parallel interface,single led backlight with yellow green color included can be dimmed easily with a resistor or PWM,stn-lcd positive,dark blue text on the yellow green color,wide operating temperature range,rohs compliant,built in character set supports English/Japanese text, see the SPLC780C datasheet for the full character set. It"s optional for pin header connection,5V or 3.3V power supply and I2C adapter board for arduino.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!".For 8051 microcontroller user,we prepared the detailed tutorial such as interfacing, demo code and Development Kit at the bottom of this page.

This repository contains all the code for interfacing with a 16x2 character I2C liquid-crystal display (LCD). This accompanies my Youtube tutorial: Raspberry Pi - Mini LCD Display Tutorial.

During the installation, pay attention to any messages about python and python3 usage, as they inform which version you should use to interface with the LCD driver. For example:

It is possible to define in CG RAM memory up to 8 custom characters. These characters can be prompted on LCD the same way as any characters from the characters table. Codes for the custom characters are unique and as follows:

/* Demonstration sketch for PCF8574T I2C LCD Backpack Uses library from https://bitbucket.org/fmalpartida/new-liquidcrystal/downloads GNU General Public License, version 3 (GPL-3.0) */

Previous examples connect the white LED backlight to power. The following example is specifically for those using an LCD with a RGB LED backlight. The only difference between the connection is the LED"s backlight on pins 15-18.

3.3V Slim Black 16x2 COG Character w/Tutorial I2C Serial LCD Display,Arduino. Description ERC160 2DN S-4 is 16 characters wide,2 row cog(chip on glass,no board) character lcd module,compact size,metal pin connection,ST7032i controller,i2c+4-wire serial interface,single led backlight with white color included can be dimmed easily with a resistor or PWM,ffstn bl ack -lcd negative,white text on the bl ack color,high contrast,wide operating temperature range,wide view angle,rohs compliant,built in character set supports English/Japanese text,see the ST7032i datasheet for the full character set. It"s easily controlled by MCU such as 8051,PIC,AVR,ARDUINO,ARM and Raspberry Pi.It can be used in any embedded systems,industrial device,security,medical and hand-held equipment. Of course, we wouldn"t just leave you with a datasheet and a "good luck!" .For 8051 microcontroller user,we prepared the detailed tutorial such as interfacing, demo code at the bottom of this page. *The product image has been photoshopped,the black color of actural product is not as black as image shows.Please refer to the below product video for more detail. 3.3V/5V 16x2 1602 Character LCD Module,White Text on Black Background,High Contrast Video will open in a new window Using the eBay App? Paste link into a browser window: [isdntekvideo] ERC1602-4 Series Display List ↓ Display Part Number Description ERC1602FYG-4 16x2 Character LCD Display Black on Yellow Green ERC1602SBS-4 16x2 Character LCD Display White on Blue ERC1602FS-4 16x2 Character LCD Display Black on White ERC1602DNS-4 16x2 Character LCD Display White on Black What"s included in the package ↓ Num Accessory Name Qty 1 16x2 Character LCD Module 1 Ebay doesn"t allow listings to contain external links,so the documents link may be invalid. Please copy the below entire link to your browser for checking our documents(at the bottom of the page) or for bulk order. https://www.buydisplay.com/default/1602-cog-lcd-module-16x2-display-character-nt7603-black-on-white Datasheet - Character LCD Module,Controller IC,Connector ↓ Format Documents Name (Downloadable) Version Language Update Date Size 16x2 Character COG LCD Module Datasheet 1.0 English May-19-2013 397K Controller IC ST7032 Datasheet 1.0 English Oct-17-2005 1.2M Tutorial - 8051 Microcontroller Demo Code,Interfacing ↓ Format Documents Name (Downloadable) Version Language Update Date Size I2C Serial Interface Demo Code 1.0 English May-20-2013 8K 4-Wire SPI Serial Interface Demo Code 1.0 English May-23-2013 6K ERC1602-4 Series Interfacing Document 1.0 English May-27-2013 157K S pecification Gross Weight (kg)0.0400 ManufacturerEastRising Continuity SupplyWe promise the long term continuity supply for this product no less than 10 years since 2015. Part NumberERC1602DNS-4 Display Format16x2 Character InterfaceI2C, 4-Wire Serial SPI IC or EquivalentST7032i AppearanceWhite on Black Diagonal SizeNo ConnectionPin Header Outline Dimension68.6(W)x26.0(H)x6.0(T)mm Visual Area64.60x16.00mm Active Area56.25(W)x11.50(H)mm Character Size2.95x5.55mm Dot (Pixel) Size0.55x0.65mm Dot (Pixel) Pitch0.60x0.70mm IC PackageCOG Display TypeFFSTN-LCD Black Touch Panel OptionalNo Sunlight ReadableYes Response Time(Typ)No Contrast Ratio(Typ)No ColorsNo Viewing Direction12:00 Viewing Angle RangeNo Brightness(Typ)No Backlight ColorWhite Color Backlight Current (Typ)15mA Power Supply(Typ)3.3V Supply Current for LCM(Max)300uA Operating Temperature-20℃~70℃ Storage Temperature-30℃~80℃ Series NumberERC1602-4 About Us We"re China-based global display manufacturer named EastRising Technology Co.,Ltd. that has a worldwide business in design, produce and sell various displays for small to large companies since 2003. Our web site is [link removed by eBay] . Link for video and image of our production line and equipment. RoHS reports for all material we used on display module. Long Term Continuity Supply Warranty We promise the long terms continuity supply and would never end.Some controller IC may stop the production,we"ll try our efforts to find the completely compatible ones.If the equivalent is unavailable, we¡¯ll make the new tooling and use the most similar IC as replacement.So you don"t have to worry even your research time is very long. Shipping Policy All products will be checked carefully and packed in good condition before shipping.We e-mail all customers with tracking information immediately after the shipment for status tracking. Item will be shipped within 1 business day after the payment has been received. Customs fees and import duties for exports are buyer"s responsibility. Warranty All products are covered under our limited warranty, which provides all products are free of functional defects for a period of one year from the date of receipt and all products are free of visual defects and missing parts for a period of 30 days from the date of receipt.If a product was damaged during shipping or the order is incorrect,you must notify us within 2 days of receipt. How to return a product First request an RMA number from our sales with the information:part number,reason for return,order number. Our sales will then either issue an RMA number, ask you for more information, or offer to help you resolve a technical problem so that the product does not need to be returned. Products must arrive here in the same condition as when you received them. You are responsible for return shipping and insurance.Please make sure your RMA number is on the shipping label and on any documents you include with the product. After we receive the product, we inspect it to determine the cause of any defect, then update by email with our findings. This process usually takes five business days.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey