shorted lcd panel factory

I had warranty to come and look at my 58’’ TV UN58TU6900PXPA and they said they had to replace the LCD panel, however the replacement part is not available and they ended up refunding me for the device, but now I have a dead device on my house and I dont believe their diagnose.

When they took the back plate of the tv I saw the white part of the lcd panel blinking, and another technician told me the LCD Panel could be shorted, does this ring a bell to anyone?

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

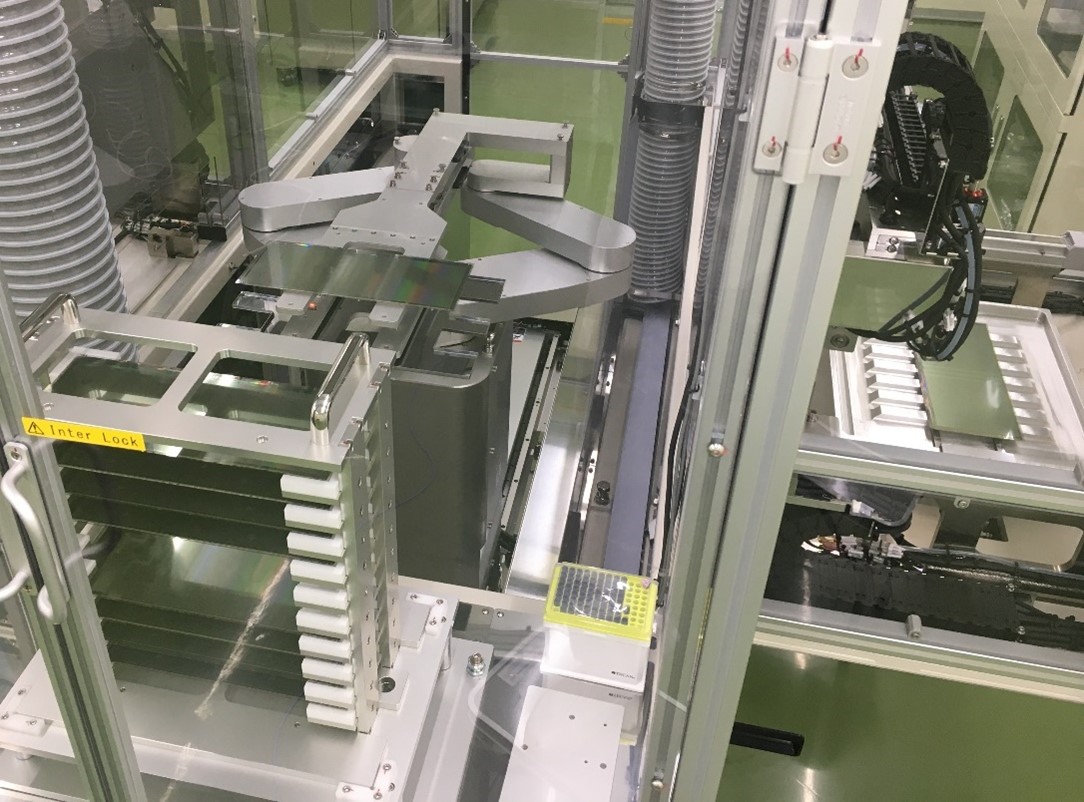

Precision cutting of semiconductor circuits, is to repair semiconductor failures ,analysis and in optical micromachining applications excellent tools for increasing productivity .Can significantly increase the of IC design engineers and fault analysis personnel productivity ,provides valuable tools for rapid removal of passivated materials and cutting circuits .The system can greatly improve the quality of production by quickly repairing defects and re-moving short circuits.On LCD screen repair industry accounted for the high-end repair technology, the most high-end technology of LCD screen repair ,LCD screen repair industry in addition to the COF loose welding ect.(This error can be repaired with a bonding machine) others such as ITO break, short line, bright line, half-line, dotted line ,a multi-line laser machine can be used to repair. Laser machine with high efficiency, fixed rate, low cost (the same fault in the laser machine does not need replacement parts, (and do not affect the repair rate), in large-scale production factory & after sale and service company are widely used ,as the main equipment for repairing screen .

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

For the first two situations, that’s because the circuit on the TFT and CF controlling that defective pixel point is shorted or broken. While the third situation is caused by damaged color pixel.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

There has been a significant shift in the global display industry lately. Apart from new display technologies, the display world is now dominated by players in Asian countries such as China, Korea, and Japan. And rightly so, the world’s best famous LCD module manufacturers come from all these countries.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a Cortex A8 1GHz Standard 256MB. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

In this post, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the reputable LCD module manufacturers in the world.

Samsung is the world’s largest semiconductor and consumer electronics manufacturer by revenue. The electronics giant is well-known for its smartphones and home appliances, but the company also manufactures LCD, LED, and OLED panels.

Probably the most in-demand and popular display panel product for Samsung is their OLED technology. Most of its current smartphones use their trademark Super AMOLED displays. The technology allowed Samsung’s smartphones to be ultra-thin, with better image brightness, and less energy consumption.

Samsung now produces panels for smart TVs. With their ever-evolving technological expertise and high-quality products, the company shows no signs of slowing down as one of the world’s best famous LCD module manufacturers.

Stone provides a professional product line that includes intelligent TFT-LCD modules for civil, advanced, and industrial use. Furthermore, Stone also creates embedded-type industrial PCs. The company’s products are all highly-reliable and stable even when used with humidity, vibration, and high temperatures.

Stone Technologies caters to a wide range of clients and industries, being among the world’s best famous LCD module manufacturers. The company’s products are used in the following industries:

Originally, LG Display was a joint venture of mother company LG Electronics and the Dutch company Phillips. They dedicated the company to creating active-matrix LCD panels. Another joint venture called LG. Phillips Displays was created to manufacture deflection yokes and cathode ray tubes.

LG Display has risen above the rest because of its world-class module products. Because of this, the company caters to a massive range of famous clients including Hewlett Packard, Apple, Sony, Dell, Acer, and Lenovo. LG Display also creates LCD modules and similar display panels for the company’s television product range.

Innolux Corporation is another famous LCD module manufacturer. This company was established in 2003 and is currently based in Zhunan, Miaoli County, Taiwan.

The company is a well-known manufacturer of display panels in Taiwan. Innolux supplies TFT-LCD and LED panels, open cells, and touch modules for the following products:

What makes Innolux stand out from other LCD module manufacturers is the company’s commitment to its humanistic qualities. Innolux believes that they are in the business to contribute to the well-being and prosperity of their customers. This is then achieved by creating world-class products that satisfy its clients.

Sharp is a Japanese company founded in 1912. It is now based in Sakai, Osaka Prefecture. The company produces various kinds of electronic products including mobile phones, LCD panels, calculators, PV solar cells, and consumer electronics. Sharp has produced TFT-LCD products as early as the 1980s.

For the regular public consumers, Sharp produces a variety of smart TVs and LCD TVs marketed under the Aquos brand. The company’s television line-up boasts of impressively high-quality technology. The TVs are equipped with technologies that support 4K and 8K UHD display, allowing for a great high-resolution viewing experience.

BOE Display is among the leading display manufacturers in the world. The company started in 1993 and is currently based in Beijing, China. Apart from display panels, BOE also manufactures smart systems using IoT technology.

The company proudly utilizes high-end technologies to create world-class display solutions. For instance, AU’s production lines can manufacture a variety of display applications in a full panel size range. The manufacturing lines also support:

Sustainability is among the ultimate goals of AU Optronics. The company takes steps to integrate green solutions into their products for more sustainable development. This commitment to sustainability, among other strong qualities, makes AU Optronics one of the best LCD manufacturers in the world.

Most of these products use TFT-LCD panels alongside other technologies to create ultra-high-definition images. Also, modern Toshiba display products incorporate IoT and artificial intelligence for a smarter product experience.

Kyocera is a Japanese LCD manufacturer. The company started in 1959 as a fine technical ceramics manufacturer but gradually added consumer electronics products to its offerings.

The Japanese company acquired Optrex Corporation in 2012. The acquisition paved the way for creating an R&D center and more production, sales, and marketing bases. Hence, Kyocera’s global LCD business boomed even more.

The company also operates factories, R&D centers, and marketing facilities in Asia, the Middle East, Europe, Africa, North and South America, and Oceania continents. Kyocera has a vast worldwide reach that makes it one of the world’s best famous LCD module manufacturers.

To wrap all this up, we listed 10 of the world’s best famous LCD module manufacturers. These are all highly-respected companies that built their reputations and climbed up the ladder of LCD module manufacturing. Their quality products, dedication to their craft, and excellent customer service truly make them among the world’s best display solutions providers.

Samsung Display will stop producing LCD panels by the end of the year. The display maker currently runs two LCD production lines in South Korea and two in China, according to Reuters. Samsung tells The Verge that the decision will accelerate the company’s move towards quantum dot displays, while ZDNetreports that its future quantum dot TVs will use OLED rather than LCD panels.

The decision comes as LCD panel prices are said to be falling worldwide. Last year, Nikkei reported that Chinese competitors are ramping up production of LCD screens, even as demand for TVs weakens globally. Samsung Display isn’t the only manufacturer to have closed down LCD production lines. LG Display announced it would be ending LCD production in South Korea by the end of the 2020 as well.

Last October Samsung Display announced a five-year 13.1 trillion won (around $10.7 billion) investment in quantum dot technology for its upcoming TVs, as it shifts production away from LCDs. However, Samsung’s existing quantum dot or QLED TVs still use LCD panels behind their quantum dot layer. Samsung is also working on developing self-emissive quantum-dot diodes, which would remove the need for a separate layer.

Samsung’s investment in OLED TVs has also been reported by The Elec. The company is no stranger to OLED technology for handhelds, but it exited the large OLED panel market half a decade ago, allowing rival LG Display to dominate ever since.

Although Samsung Display says that it will be able to continue supplying its existing LCD orders through the end of the year, there are questions about what Samsung Electronics, the largest TV manufacturer in the world, will use in its LCD TVs going forward. Samsung told The Vergethat it does not expect the shutdown to affect its LCD-based QLED TV lineup. So for the near-term, nothing changes.

One alternative is that Samsung buys its LCD panels from suppliers like TCL-owned CSOT and AUO, which already supply panels for Samsung TVs. Last year The Elec reported that Samsung could close all its South Korean LCD production lines, and make up the difference with panels bought from Chinese manufacturers like CSOT, which Samsung Display has invested in.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

The most basic LCD introduced above is called passive matrix LCDs which can be found mostly in low end or simple applications like, calculators, utility meters, early time digital watches, alarm clocks etc. Passive matrix LCDs have a lot of limitations, like the narrow viewing angle, slow response speed, dim, but it is great for power consumption.

In order to improve upon the drawbacks, scientists and engineers developed active matrix LCD technology. The most widely used is TFT (Thin Film Transistor) LCD technology. Based on TFT LCD, even more modern LCD technologies are developed. The best known is IPS (In Plane Switching) LCD. It has super wide viewing angle, superior image picture quality, fast response, great contrast, less burn-in defects etc.

IPS LCDs are widely used in LCD monitors, LCD TVs, Iphone, pads etc. Samsung even revolutionized the LED backlighting to be QLED (quantum dot) to switch off LEDs wherever light is not needed to produce deeper blacks.

– Twisted Nematic Display: The TN (Twisted Nematic) LCDs production can be done most frequently and used different kinds of displays all over the industries. These displays are most frequently used by gamers as they are cheap & have quick response time as compared with other displays. The main disadvantage of these displays is that they have low quality as well as partial contrast ratios, viewing angles & reproduction of color. But, these devices are sufficient for daily operations.

– In-Plane Switching Display:IPS displays are considered to be the best LCD because they provide good image quality, higher viewing angles, vibrant color precision & difference. These displays are mostly used by graphic designers & in some other applications, LCDs need the maximum potential standards for the reproduction of image & color.

– Vertical Alignment Panel: The vertical alignment (VA) panels drop anywhere in the center among Twisted Nematic and in-plane switching panel technology. These panels have the best viewing angles as well as color reproduction with higher quality features as compared with TN type displays. These panels have a low response time. But, these are much more reasonable and appropriate for daily use.

– The structure of this panel generates deeper blacks as well as better colors as compared with the twisted nematic display. And several crystal alignments can permit for better viewing angles as compared with TN type displays. These displays arrive with a tradeoff because they are expensive as compared with other displays. And also they have slow response times & low refresh rates.

– Advanced Fringe Field Switching (AFFS): AFFS LCDs offer the best performance & a wide range of color reproduction as compared with IPS displays. The applications of AFFS are very advanced because they can reduce the distortion of color without compromising on the broad viewing angle. Usually, this display is used in highly advanced as well as professional surroundings like in the viable airplane cockpits.

– Passive and Active Matrix Displays: The Passive-matrix type LCDs works with a simple grid so that charge can be supplied to a specific pixel on the LCD. One glass layer gives columns whereas the other one gives rows that are designed by using a clear conductive material like indium-tin-oxide. The passive-matrix system has major drawbacks particularly response time is slow & inaccurate voltage control. The response time of the display mainly refers to the capability of the display to refresh the displayed image.

– Active-matrix type LCDs mainly depend on TFT (thin-film transistors). These transistors are small switching transistors as well as capacitors which are placed within a matrix over a glass substrate. When the proper row is activated then a charge can be transmitted down the exact column so that a specific pixel can be addressed, because all of the additional rows that the column intersects are switched OFF, simply the capacitor next to the designated pixel gets a charge.

LCD technologies have great advantages of light, thin, low power consumption which made wall TVs, laptops, smartphones, pad possible. On its way to progress, it wiped out the competition of many display technologies. We don’t see CRT monitors on our desks and plasma displays TV at our home anymore. LCD Technologies dominant the display market now. But any technology has the limitations.

LCD technologies have slow response times especially at low temperature, limited viewing angles, backlighting is needed. Focus on LCD drawbacks, OLED (Organic Light Emitting Diodes) technology was developed. Some high-end TV and mobile phones start to use AMOLED (Active Matrix Organic Light Emitting Diodes) displays.

This cutting-edge technology provides even better color reproduction, clear image quality, better color gamut, less power consumption when compared to LCD technology. Please note, OLED displays include AMOLED and PMOLED (Passive Matrix Organic Light Emitting Diodes). What you need to choose is AMOLED for your TV and mobile phones instead of PMOLED.

By Lee Kyung-minSamsung Display has decided to close its liquid-crystal display (LCD) business in June, hobbled by a declining global competitive edge due to cheaper products made by its Chinese and Taiwanese counterparts, according to the industry, Sunday. No investment plan details have since been announced.The decision by the display affiliate of Samsung Group came six months sooner than expected, due in large part to rapid losses from falling LCD prices.According to Display Supply Chain Consultants (DSCC), a U.S. market research firm, the average price index of LCD panels, measured against 100 in January 2014, will fall to 36.6 in September of this year. The figure has dropped farther from the record low of 41.5 in April of this year, and 58 percent lower than the record high of 87 in June 2021.Also factored in was Samsung Electronics, the largest buyer of Samsung Display products, partnering with overseas LCD suppliers, including BOE Technology Group, a Chinese electronic components producer and AU Optronics Corp. (AUO), a Taiwanese LCD panel maker.The display affiliate initially sought to close its LCD business in late 2020, but the plan was delayed at the request of its parent company, Samsung Electronics, due to a sudden spike in LCD prices amid the COVID-19 pandemic.Samsung Display will no longer produce LCDs used for large TV screens and focus instead on manufacturing organic light-emitting diode (OLED) and quantum dot (QD) displays. The employees of the LCD businesses are expected to be transferred to the QD businesses.The display affiliate was first formed in 1991, as an LCD business arm under Samsung Electronics. It formally launched in 2012 as Samsung Display and has since merged with three local and Japanese makers of active matrix organic light-emitting diodes (AMOLED), for the production of advanced types of displays.Samsung Display was unavailable for comment.

Unlike plasma TVs, LCD TVs use a backlight. Initially, LCD TVs used Cold-Cathode Fluorescent Lamp (CCFL) as their backlight. These are long tubes that are placed horizontally across the screen behind the LCD panel. When the light is turned on, it applies a voltage to the pixels, which makes them rotate a certain way to allow light through and produce an image. When it wants to display black, the pixels are rotated to create an opaque screen so that light doesn"t get through. This is what makes them different from plasma TVs because each pixel isn"t self-emitting.

Light-Emitting Diode (LED) TVs are the same as traditional LCD TVs, but instead of using CCFL backlights, they use many smaller LED lights. It produces an image the same way as a regular LCD TV because it still uses an LCD panel, but it has more control over the backlighting. The LEDs can be placed along the edges, which is called edge-lit LED, or all over the back panel, which is either called direct LED or full-array backlighting. You can see the differences between LCD and LED TVs below.

It"s also important to note LED is simply a marketing term used by manufacturers to describe their backlight. They"re still technically LCD TVs, but since calling them LED is so common now, we even label them as LED, and we"ll continue to do so throughout this article.

On the other hand, LED TVs can"t achieve a perfect black level because the backlight is always on. However, technology has evolved to greatly improved the contrast of LED TVs, even to the point where it"s also as good as what plasma once was. There are two main types of LCD panels in TVs: Vertical Alignment (VA) and In-Plane Switching (IPS). VA panels produce a better contrast than IPS, and high-end TVs also have local dimming features that turn off certain zones of the LED backlights. Still, you won"t get a perfect black level, but most modern LED TVs produce such deep blacks that even in a dark environment it looks like perfect black levels. For reference, plasma TVs had a max contrast of about 4,000:1, according to DisplayMate.com, but some recent LED TVs can reach a contrast of over 20,000:1 with local dimming enabled, like the Samsung QN90A QLED.

LED TVs are a clear winner here, and it"s one of the reasons why they surpassed plasmas in terms of popularity. LED TVs get significantly brighter, so they can fight glare from light sources easier. Additionally, plasma TVs had to use glass on their front panel, which caused intense glare if you had any lamps or windows around the TV. LED TVs can use a coating on their glass panel to help reflect and diffuse light, making it a better choice for well-lit rooms.

Pixels on plasma TVs emitted light in all directions, creating extremely wide viewing angles, much better than most LED TVs. This means that the image remained accurate when viewing from the side, which was great for watching sports or a show with a few people. Out of the two main panel types for LED TVs, IPS has wider viewing angles than VA panels, but it"s still not as good as plasma.

TV manufacturers have tried different technologies to improve viewing angles on VA panels. Samsung has an "Ultra Viewing Angle" layer, and Sony uses their "X-Wide Angle" technology to increase the viewing angles, both at the cost of a lower contrast ratio. It"s still not as good as plasma, but they"re wide enough for watching TV in a fairly large seating area.

Below you can see the differences in viewing angles between a plasma and a VA panel. These TVs were tested on different test benches, so you shouldn"t directly compare the videos, but we included them to give you an idea of how each technology affects the viewing angle.

Screen uniformity is another area where plasma TVs win. Since they didn"t have a backlight, they could evenly control each pixel. LED TVs can suffer from uniformity issues, like darker edges or Dirty Screen Effect in the center, because the backlight output may not be even across the panel. However, this is only really noticeable when watching content with large areas of uniform color, like a hockey or basketball broadcast, or if you"re going to use the TV as a PC monitor. It shouldn"t be noticeable with other types of content, and since uniformity can vary between units, you shouldn"t worry about it too much.

Due to their different technologies, LED and plasma TVs are built differently. Plasma TVs tended to be heavier and thicker because the panel itself was larger. Although plasmas were the first flat-screen TVs available at a consumer level at the end of the 20th century, LCD TVs quickly became even thinner, easier to package, and lighter to carry from the store to your house. These days, LED TVs are as thin as 1", like the Samsung QN85A QLED.

Both plasma and LED TVs were made with larger sizes, but LED had a slight advantage because they were also made in displays smaller than 32 inches, like with monitors. Although small TVs are rare now, you can still find a basic 28 or 32 inch TV for a kitchen or bedroom with an LED panel. Plasma TVs weren"t made that small. LED TVs also cost less to produce and are cheaper on the market, so at the end of the day, the lower cost drove LED sales.

Although plasma TVs once dominated the TV market for a short time at the turn of the 21st century, their disadvantages outweighed their advantages, and LED-backlit LCD TVs soon held the market share of sales. There were a few reasons for this, like burn-in issues, low peak brightness, and a thick and heavy design compared to LED TVs. Despite plasma TVs" superior overall picture quality, improved contrast, and very quick response time, it wasn"t enough to convince consumers to keep buying them once 4k LED TVs became readily available. If you still have a plasma, it"s likely you"ll need to replace it within the next few years, and you"ll probably buy a new LED TV.

(Reuters) - Foxconn Technology Group is reconsidering plans to make advanced liquid crystal display panels at a $10 billion Wisconsin campus, and said it intends to hire mostly engineers and researchers rather than the manufacturing workforce the project originally promised.

Foxconn, which received controversial state and local incentives for the project, initially planned to manufacture advanced large screen displays for TVs and other consumer and professional products at the facility, which is under construction. It later said it would build smaller LCD screens instead.

Rather than a focus on LCD manufacturing, Foxconn wants to create a “technology hub” in Wisconsin that would largely consist of research facilities along with packaging and assembly operations, Woo said. It would also produce specialized tech products for industrial, healthcare, and professional applications, he added.

Rather than manufacturing LCD panels in the United States, Woo said it would be more profitable to make them in greater China and Japan, ship them to Mexico for final assembly, and import the finished product to the United States.

He said that would represent a supply chain that fits with Foxconn’s current “fluid, good business model.”FILE PHOTO: A shovel and FoxConn logo are seen before the arrival of U.S. President Donald Trump as he participates in the Foxconn Technology Group groundbreaking ceremony for its LCD manufacturing campus, in Mount Pleasant, Wisconsin, U.S., June 28, 2018. REUTERS/Darren Hauck

The difference between a LED TV and a LCD TV is that they are both LCD TV’s except one has LED stripes and the other has CCFL Backlights- (Florescent Tubes). I used a Philips Magnavox Emerson LG TV when testing these repaird, but they should work on other TV brands that are similar. Before you do any Repair, check to see if you are still under warranty, or are covered by a recall of your TV!!

If your Plasma or LCD/LED or CCFL/LCD TV or monitor has stopped working, or is displaying one of the following symptoms, then it *may* need some new capacitors in the power supply board or a replacement board

If the TV is still locked and will not respond to any commands from the front panel control buttons or the remote control unit, it is apparently locked in a failure or diagnostic mode, and would probably have to be diagnosed and repaired by a reputable TV repair facility. Good luck.

If it is a thin vertical line that appears on certain video resolution/image then it is normal and is indicated in the users manual under troubleshooting. If the line is almost half the screen, it could be a problem with the cable connection between the LCD panel and logic board, or the LCD panel itself. Try reseating the cable first if it’ll solve the problem. I’ve done similar issue in the past. Reseating the cable worked for a couple of months till eventually the LCD panel is the problem. Replacing the LCD panel is quite costly and impractical.

If the lines are there all the time or intermittent but in the same location it is an indication of a bad panel. The panel driver can also be the cause of this symptom.

If the lines/bars are across the OSD Menu, and all the video signal inputs also same result, that means the TV LCD Panel is defective Most of the time this symptom is caused by a bad LCD Panel 95%. You can try refitting LVDS Cable or replacing Main Board capacitors or replacing Main Board—5%

Bad news unfortunately, their are two possible causes for what you have described, one would be a fault with the picture drive pcb ( Power Control Board ), and the other is physical damage to the LCD cell matrix, (screen).

There’s videos on how to fix this. It has to do with putting foam, in between panel frame and screen, which applies pressure to solder joints, which then completes the circuit- Contact my10cents, for better explanation.

Is the OSD menu affected as well? If yes then possibility could be the LCD Panel or the t-con board. Since you have replaced the t-con board then possibility is the LCD panel. There could be also a possibility of mainboard where upgrading the firmware could restore the picture. If the OSD menu is not affected then the LCD panel is good.

If the lines are across the OSD menu then chances is very high the LCD panel is the cause of the problem otherwise it can be due to bad T-con board or even Mainboard. Have you tested on the OSD menu to see if the lines are really across the menu?

White Lines– There are several possibilities that can cause white lines on an lcd screen. One would be high temperature on the logic board. Logic board drives the LCD panel and when it overheats can cause this display problem. One solution would be to clean the vent holes around the TV. One possibility that I have experienced myself servicing is a bloated capacitor on the power supply board. The worst possibility is a defective LCD panel, which is costly to repair, and sometime more practical to buy a new TV set.

There are several problems that could cause this problem. It could be the connection from the T-Con board to the panel, try wiggling these cables around and see if the picture comes up even for a second. The Mainboard or it’s cables are not the issue in my opinion. The isdsue is either going to be a bad capacitor, faulty output from the power supply to the T-Con board, a bad connection from T-Con to panel, or the T Con or the panel itself are faulty.

It could be the connection from the T-Con board to the panel, try wiggling these cables around and see if the picture comes up even for a second. The Mainboard or it’s cables are not the issue in my opinion. This is due to either a bad capacitor, faulty output from the power supply to the T-Con board, a bad connection from T-Con to panel, or the T Con or the panel itself are fault. Also, it’s possible the A/V receiver’s Video On feature was turned off by an electrical surge or something else.Turn the Video feature back to On and suddenly that bad blue screen was gone.

Now we need to know if PSU Board has all the correct output voltages. This means checking the secondary side output voltages of Power Board. Probable causes are the Power Supply, the T-Con board, Main Board or the LCD panel itself has failed.

You will have to go into the TV and check for capacitors or burn marks or cracked solder around the pins–Main board could be IC’s, or regulators–Panel–Disconnect panel and see if your TV stay’s on—

The flashing green light indicates a fault on the power board inside your TV. This will be due to a faulty component like a capacitor or voltage regulator. Faulty electrolytic capacitors on the power board are the most common cause of this problem. These capacitors will often leak and stop working as the TV set gets older,but could also be caused by the Main Board or the inverter board. (LCD TV ONLY) So we will have to take a look inside and maybe do some circuit testing and a visual of your boards-

In a dark room take a flashlight and at an angle shine it on the screen and see if you can see any movement. If you can see movement or see your menu then its backlight failure. If totally black screen with sound then its T-Con board. So if you see movement on a led screen, then it’s your LEDs inside the panel. If on a LCD TV you see movement and lamps are not turning on, replace inverter. If with a LCD TV your lamps turn on, with no picture replace T-Con Board.

Plasma is the most durable in terms of panel failure. LED/LCD is terrible for panel failure. (But every model gets bad apples. Samsung LED/LCD panels die frequently. LG panels are a lot more reliable.) Overall I’d say plasma is more reliable, and even if it fails, in most cases plasma is repairable, LED/LCD is expensive to repair and often difficult to troubleshoot.

A blurry image on a high-definition LCD TV is typically the result of a mismatch between the TVs resolution capabilities and the resolution of the signal that is coming from connected devices, such as a DVD player or satellite TV receiver. Typically, blurry pictures result when a peripheral device connects to the TV through non HD cables and jacks.

Flat panel displays use different backplane technologies. Small and medium OLEDs for mobile phones use a low temperature polysilicon (LTPS) backplane which is created by laser annealing amorphous silicon (a-Si). OLED TVs use a metal oxide backplane. Both backplanes use deposited thin films which must be highly uniform and contamination free to maximize electrical performance. The OLEDs are evaporated or deposited and encapsulated to reduce degradation caused by water vapor and oxygen exposure. Encapsulation uses either strengthened glass or thin films, depending on whether the OLED is rigid or flexible. Dissimilarity of materials within the rigid and flexible stacks make cutting and singulation of individual display devices a challenge. The highly complex nature of this process can induce defects, decreasing throughput and yield.

This is a common problem in TVs and is a sign that your TV panel is failing. But before you call an expert to check the TV, you could try following these steps and check if they work:

If it continues to show lines, you may mostly have to get the panel replaced and replacing the panel can be a costly affair, depending on the TV and its model. LED panels range anywhere between Rs 8,000 to Rs 85,000, while LCD panels range between Rs 6,000 to Rs 25,000.

When the TV has speakers that work perfectly fine but it has no picture, there is mostly an issue with the back-lighting system or the power supply board, which will need to be replaced. In the case of an LCD TV, it works with the help of a backlight that is used to illuminate the picture on the screen. When the backlight begins to have problems, the screen turns blank.

To fix this issue, the backlight will have to be replaced by a TV expert. Another possible reason is that the backlight on the LCD TV which has a power inverter has failed. When this happens, you may need to replace the inverter or the capacitor.

Be it a panel issue or a major technical issue with the TV, resolving these problems is a costly affair. It’s best not to ignore any of these signs and call an authorized TV expert before the problem worsens.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey